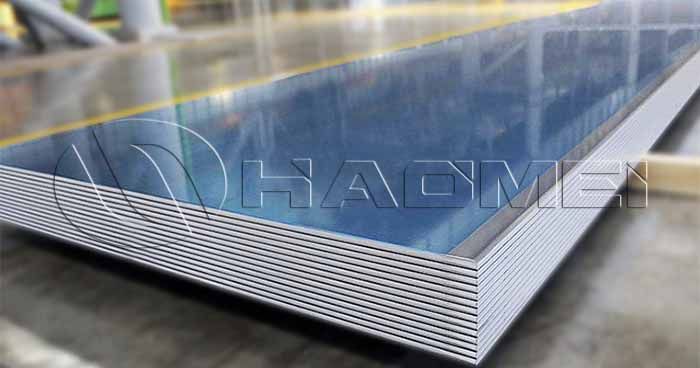

2024 aircraft aluminum belongs to the Al-Cu-Mg high strength deformed aluminum alloy, which is widely used in aviation, aerospace and other military products. The heat treatment state often used in aviation components is T42 (Solid Solution + Natural Aging). For example, many 2024 aluminum alloys used in aviation products such as Boeing and Airbus are in T42.

2024 aluminum alloy The compressive strength of 2024 aluminum alloy is higher than that of 7075 aluminum alloy. The forming characteristics are better under quenching and new heat treatment conditions, and the heat treatment process enhancement can achieve an ideal effect. The corrosion resistance is weak, but it can be reasonably maintained with pure aluminum coating.

2024 aluminum properties vary significantly depending on the heat treatment state. After solution treatment, the natural aging state has higher tensile strength and toughness, and the artificial aging state has higher yield strength and corrosion resistance.

Its comprehensive mechanical properties and high-temperature creep resistance are excellent, and the high-temperature softening tendency is small. 2024 alloy is commonly used in aircraft structures, bolts, truck wheels, aircraft propeller components and many other parts.

With the development of the aviation industry, the requirements for the high temperature resistance of materials are getting higher and higher. in an emergency, a high temperature of 204 ℃ may appear in the short-term dive state. This kind of creep under long-term thermal environment will affect the material structure of the aircraft.

The related research shows that showed that: compared with peak aging, the precipitated phase in the supersaturated solid solution increased the creep resistance of the alloy during the under-aging process. After underaging treatment, the steady-state creep rate of 2024 aluminum alloy is significantly reduced.

Original Source:https://www.aircraftaluminium.com/a/what-are-the-2024-aluminum-properties.html