7075 aluminum for sale is a typical aviation super-duralumin. It is not only an "old" AL-Zn-Mg-Cu alloy, but also a young alloy with strong "energy". This was the first finalized super duralumin, which was finalized in 1944. It was used to make airplanes in the United States, Japan, and the former Soviet Union. It is only 74 "years old" and is still in the "middle-aged" stage.

It is "young" because it is now the main material for the key structure of aerospace vehicles. It seems that super duralumin will only withdraw when composite materials can be produced in large quantities and the price is reduced to be competitive with super duralumin.

After more than 70 years of development, 7075 alloy has formed a considerable family. Now the commonly used alloys are 7075/7175/7475 alloys. 7275 alloys have been less used due to their unsatisfactory performance. 7375 alloys have been completely eliminated.

After more than 70 years of development, 7075 alloy has formed a considerable family. Now the commonly used alloys are 7075/7175/7475 alloys. 7275 alloys have been less used due to their unsatisfactory performance. 7375 alloys have been completely eliminated.

Among the 7075/7175/7475 alloys, 747 has the lowest impurity content. For example, the silicon content of 7475 alloy is only 25% of 7075 alloy, therefore it has higher toughness and better overall performance.

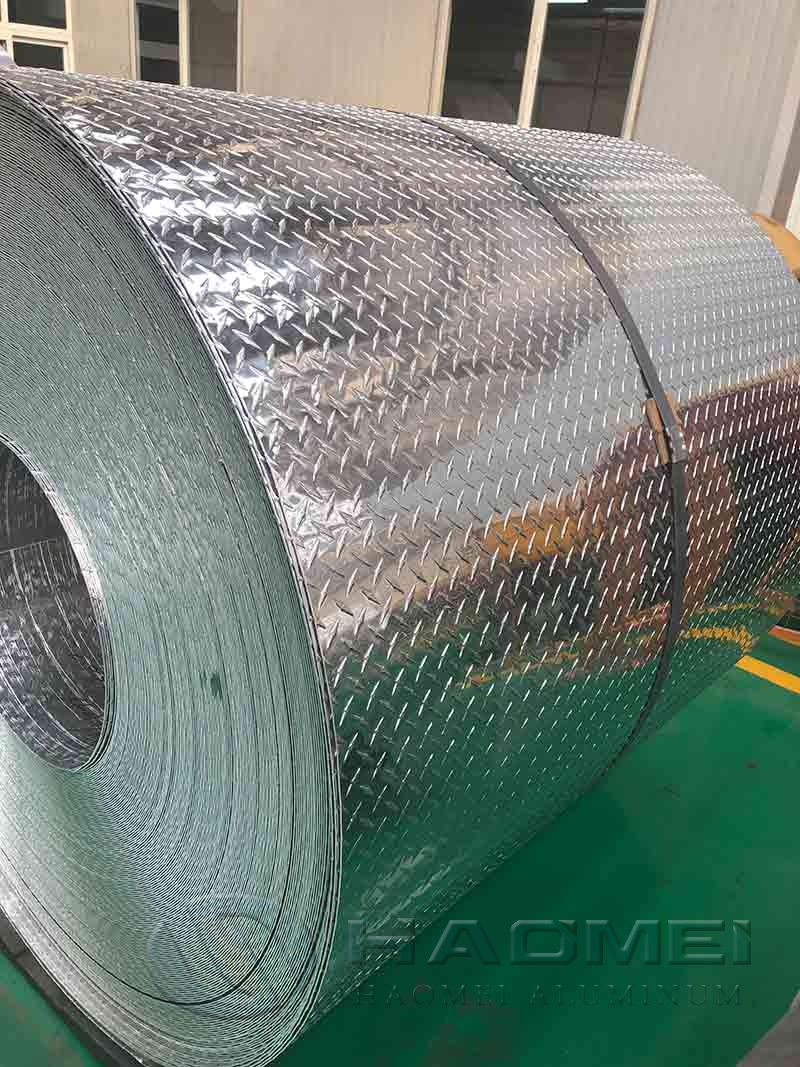

7075 aluminum alloy is an Al-Zn-Mg-Cu high-strength deformed aluminum alloy that can be heat-treated and strengthened. It is used to manufacture various structural parts, especially aerospace vehicle structural parts. It is the most widely used high-strength aluminum alloy today.

Its application range from C919 large aircraft front fuselage long truss, passenger observation window frame forgings, middle fuselage sheet bending and long truss, keel beam web, floor turning beam, middle and rear fuselage long truss to cell phone casings.

7075 grade aluminum has many tempers: T6, T73, T76 and T77. 7075 T6 Aluminum has the highest mechanical strength performance, but the fracture toughness is low and is sensitive to stress corrosion. Its toughness decreases with the decrease of temperature. Therefore, 7075 T6 aluminum is not suitable for manufacturing low-temperature structural parts and work pieces.

7075 thick aluminum plate and its extruded profiles will generate a lot of internal stress after quenching. They must be stretched before aging treatment to reduce them to the allowable range. Therefore, this kind of stretching is called pre-stretching. The pre-stretching amount is 1.5%~3%, otherwise serious deformation will occur.

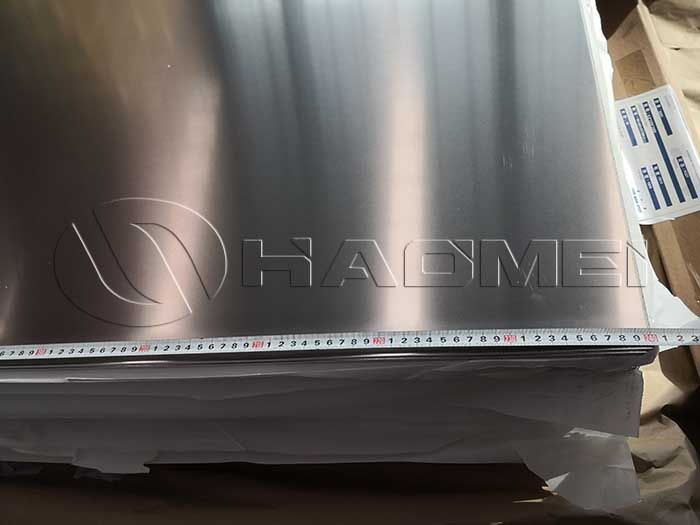

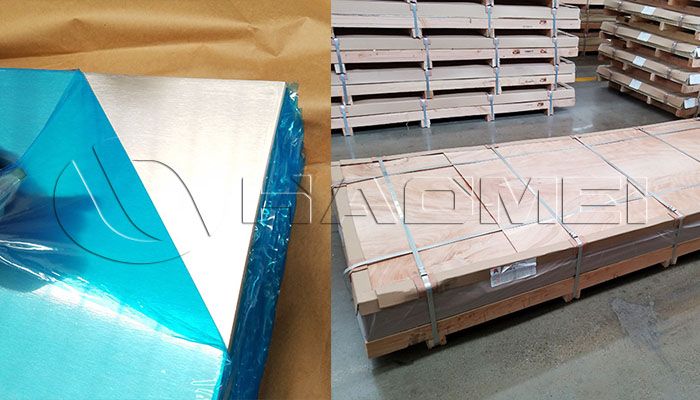

Haomei is a big 7075 aluminum plate suppliers, providing free sample test and cooperate with many aircraft parts manufacturers at home and abroad. Welcome to leave message below to inquire it.

Original Source:https://www.aircraftaluminium.com/a/the-typical-super-duralumin-7075-aluminum-for-sale.html