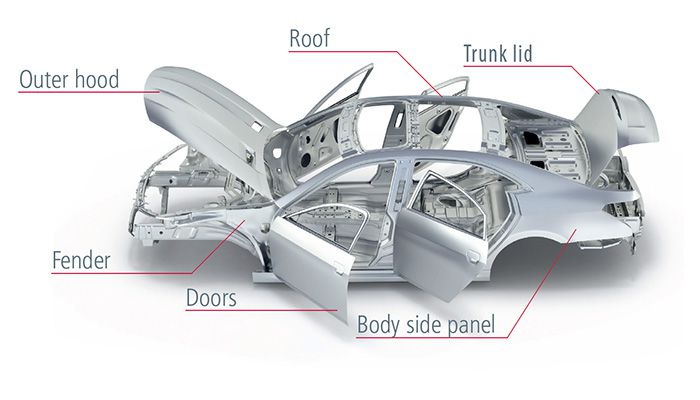

After the rapid development of automobile industry, people's requirements for automobiles are no longer limited to functions, and there are also higher requirements for the overall body. The lightweight car can not only effectively reduce the weight of the car body, but also achieve energy saving and emission reduction.

The aluminum body panels are the commonly used lightweight material. The required performance can be achieved by increasing or reducing the ratio of alloying elements and adopting appropriate heat treatment processes. At present, the main aluminum alloys used for body panels are AL-Cu (2000 series), AL-Mg (5000 series) and AL-Mg-Si (6000 series).

6xxx aluminum alloy has become the first choice for many automobile manufacturers due to its good plasticity and high strength. For different parts and components of the car body, the alloy composition, types and heat treatment process are also different.

6016 aluminum sheet has good forming properties and bake hardening properties, and is widely used in those parts including hood panel, car door, trunk lid, roof panel,etc. It is a special aluminum body panel.

The strength of ordinary steel for automobiles is about 240MPa, the strength of high-strength steel is 500-700MPa, and the strength of 6016 aluminum for automobiles can reach more than 500MPa. Therefore, the specific strength (strength/density) of 6016aluminum alloy is higher.

Haomei 6016 aluminum can be used in various parts and bodies of automobiles. Hemming is an important process in the assembly of the inner and outer panels. An important indicator to measure the hemming performance of 6016 aluminum sheet is the bending limit. 6016-O aluminum is suitable for various bending processing.

Original Source:https://www.autoaluminumsheet.com/a/6016-aluminum-for-lightweight-car.html

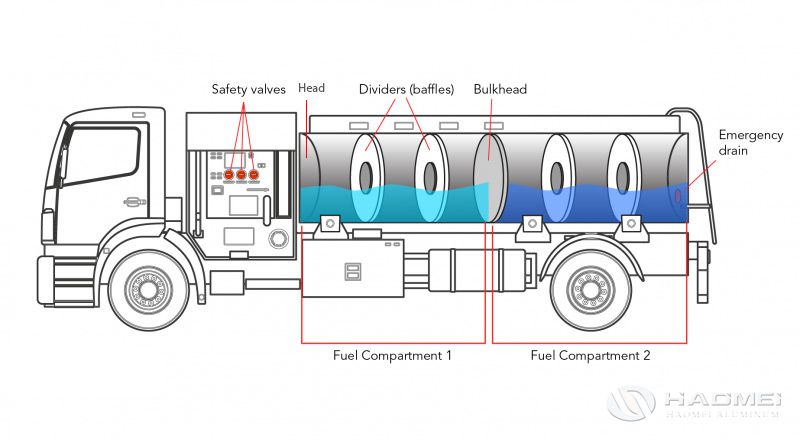

The fuel tanker is used for the transportation of gasoline, crude oil, various viscous oils, vegetable oils, liquid ammonia, wine, water, various acid-base liquids. The raw material can be stainless steel or aluminum alloy.

The fuel tanker is used for the transportation of gasoline, crude oil, various viscous oils, vegetable oils, liquid ammonia, wine, water, various acid-base liquids. The raw material can be stainless steel or aluminum alloy.