What is fuel tanker

The fuel tanker is used for the transportation of gasoline, crude oil, various viscous oils, vegetable oils, liquid ammonia, wine, water, various acid-base liquids. The raw material can be stainless steel or aluminum alloy.

The fuel tanker is used for the transportation of gasoline, crude oil, various viscous oils, vegetable oils, liquid ammonia, wine, water, various acid-base liquids. The raw material can be stainless steel or aluminum alloy.

Compared with carbon steel tankers, the aluminum alloy tanker is lighter ,which reduces fuel consumption and tire wear during transportation, thereby reducing daily operating and maintenance costs. Aluminum alloy has strong corrosion resistance and improves tanker service life.

The advantage of aluminum plate for fuel tanker

1. Lightweight tank body

Since the density of aluminum alloy is small, it is more than 4 tons lighter than similar carbon steel tankers and loads 20% more than carbon steel tankers. The large cross-section beam is extruded at one time, the strength is high.

2. Strong corrosion resistance

Aluminum alloy has good compatibility with most chemical media such as acetone, benzene, gasoline and diesel, kerosene, glacial acetic acid and food, and has a wide transportation range. It has no need for special surface treatment, saving maintenance cost.

15-20 years is the typical service life of aluminum alloy load tankers. According to the statistics of American HEIL company, the average service life of aluminum alloy tankers is about 10 years, depending on the customer's use and maintenance conditions. The longest service life of aluminum alloy tankers has reached 40 years.

3. Good ductility

Tank body made of aluminum sheet is of good elongation and high strength. Oil products are flammable and explosive dangerous goods, so safety is an important indicator for the tank trucks. Oil products are prone to thermal expansion and contraction in extreme cold or hot conditions. The ductility of ordinary oil tanks is prone to explosion in this case. The use of aluminum alloy tanks greatly improves safety.

4. High recycling value

Aluminum sheet has a very high recycling value. A tank made of 5 tons of aluminum plate will bring about 15,000$ when the fuel tank is recycled according to the international aluminum scrap price.

The use of aluminum plate for oil tank truck

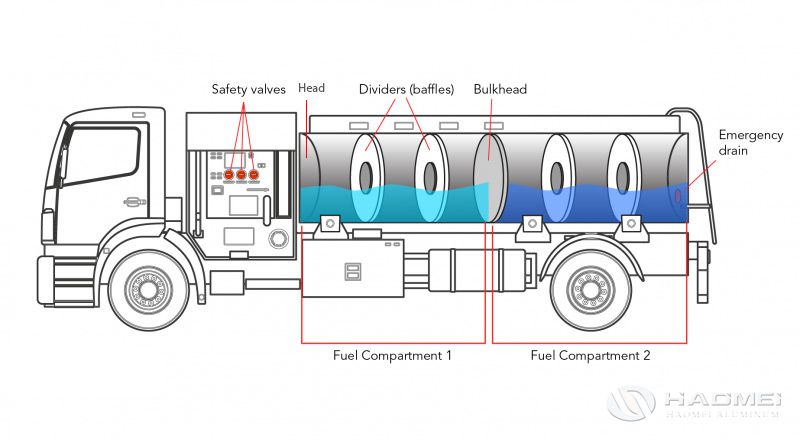

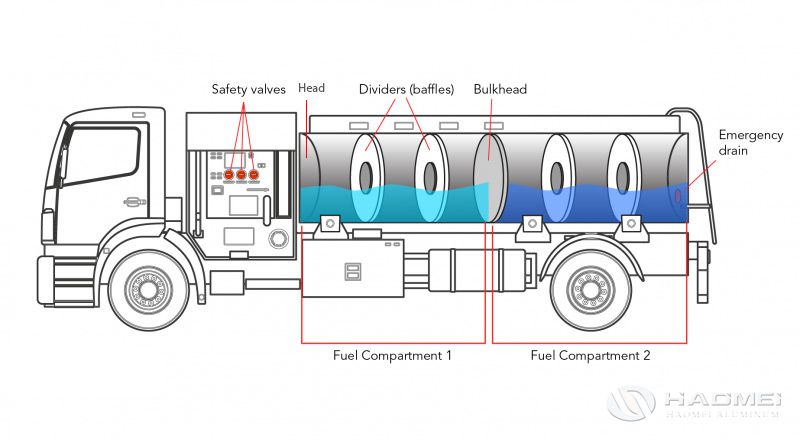

The aluminum plate for tank body is welded with 5083 aluminum alloy plate. The plate thickness is 5~6mm.

The other parts like wash board, bulkhead and tank head is also of 5083 aluminum plate. The wall thickness of the tanker head is equal to or greater than that of the tank body. The thickness of the bulkhead and wash board is 1mm thinner than the tank body.

The thickness of the left and right support plates at the bottom of the tank is 6-8mm, and the material is 5A06 aluminum plate. There are guardrails and walking platforms on the top of the tank. The walking platforms are made of aluminum tread plate.

The aluminum plate for tank body is welded with 5083 aluminum alloy plate. The plate thickness is 5~6mm.

The other parts like wash board, bulkhead and tank head is also of 5083 aluminum plate. The wall thickness of the tanker head is equal to or greater than that of the tank body. The thickness of the bulkhead and wash board is 1mm thinner than the tank body.

The thickness of the left and right support plates at the bottom of the tank is 6-8mm, and the material is 5A06 aluminum plate. There are guardrails and walking platforms on the top of the tank. The walking platforms are made of aluminum tread plate.

Alloys of aluminum sheet for fuel tank

5083 aluminum sheet is a widely used in the manufacturing of fuel trucker. Its main element is magnesium, which has good welding performance, corrosion resistance and processing performance and medium strength.

5182 aluminum plate is used for the the latest high-magnesium alloy tanker which was born for the European road dangerous goods transportation agreement in recent years. Its tensile strength and elongation are relatively high. The excellent quality of 5182 alloy plate improves the safety of aluminum alloy tankers.

5454 aluminium plate is suitable for aluminum-magnesium alloy tankers used under high temperature conditions, with strong corrosion resistance.

Original Source:https://www.aluminumtankerplate.com/aluminum-plate-for-fuel-tanker

5083 aluminum sheet is a widely used in the manufacturing of fuel trucker. Its main element is magnesium, which has good welding performance, corrosion resistance and processing performance and medium strength.

5182 aluminum plate is used for the the latest high-magnesium alloy tanker which was born for the European road dangerous goods transportation agreement in recent years. Its tensile strength and elongation are relatively high. The excellent quality of 5182 alloy plate improves the safety of aluminum alloy tankers.

5454 aluminium plate is suitable for aluminum-magnesium alloy tankers used under high temperature conditions, with strong corrosion resistance.

Original Source:https://www.aluminumtankerplate.com/aluminum-plate-for-fuel-tanker

没有评论:

发表评论