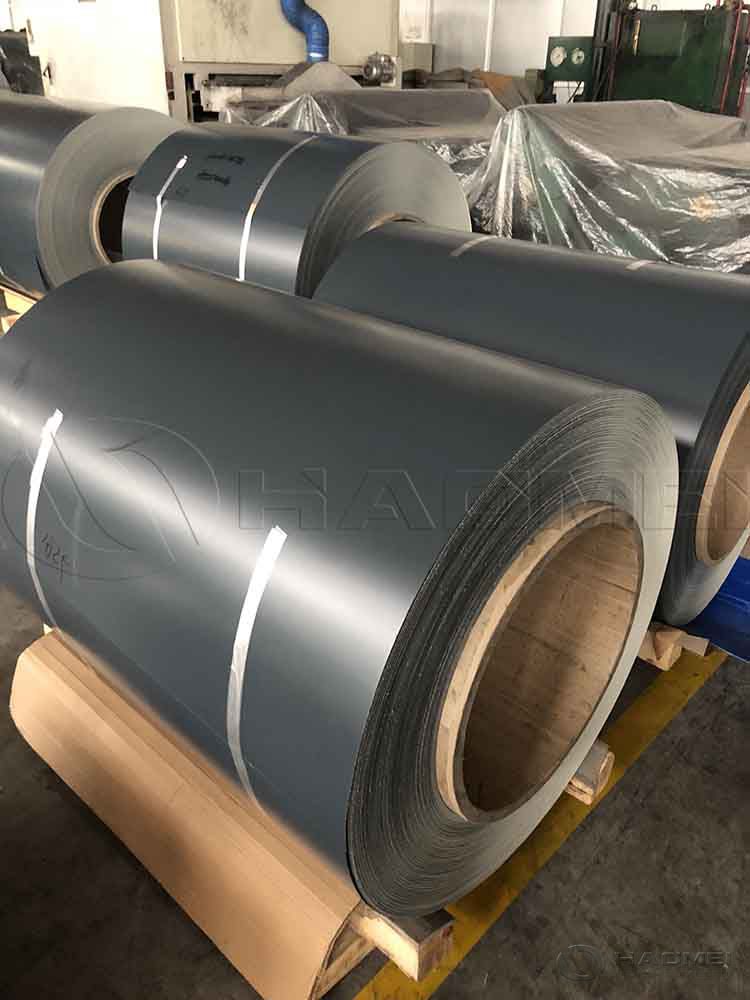

The color coated aluminum coil refers to a material that is surface-coated to form a variety of colors to improve the oxidation protection performance and aesthetics of the aluminum coil. In daily life, color-coated aluminum coils are widely used in construction, decoration, automobiles, electrical appliances, packaging and other fields, and have become an important part of many products.

It has the advantages of both aluminum sheets and organic materials. The aluminum trim coil has the mechanical strength, good toughness, and easy processing and molding of aluminum sheets, but also have the good coloring, decoration, and corrosion resistance of organic polymer coating materials. It is easy to perform punching, bending, deep drawing, welding and other processing.

Because there are many aluminum trim coil colors, Haomei Aluminum generally does not have them in stock. The colors can be customized according to the RAL color card or other standard color card numbers, or they can be color-matched and processed according to samples, so color-coated aluminum coils require a certain period of time. Users should consider the processing time when ordering, and try to order in advance to avoid being late for processing.

The processing cycle of fluorocarbon color-coated aluminum coils is generally longer, mainly because the fluorocarbon paint uses Nippon Paint, and Nippon Paint's paint blending is all standardized. Color mixing will be carried out after the laboratory data is stable, so the delivery time of the PVDF coated aluminum coil is around 15 days. If we have aluminium coil in stock, the delivery time can be shortened to around 7 days.

The processing cycle of polyester color-coated aluminum coils is slightly shorter, because the color mixing of polyester paint is relatively simple. Generally, the processing cycle of the PE coated aluminum coils is about 2 days faster, mainly because the color mixing time is shorter.

Applications of painted aluminum coils

In terms of construction, the pre painted aluminium coil can be made into building exterior wall insulation materials, profiled panels, roof panels, ceilings, etc. It can provide a wide range of color choices and textures, and can also enhance the waterproof, anti-oxidation, and fire-proof capabilities of building exterior walls and roofs. They also have excellent sound absorption and decorative properties, making them beautiful and practical.

In terms of automobiles, color-coated aluminum coils can be made into automobile exterior decorative parts, such as doors, hoods, etc. Color-coated aluminum coils are lightweight, wear-resistant and low-cost, so they are widely used in the automotive industry.

In terms of electrical appliances, color-coated aluminum coils can be made into the casings of refrigerators, washing machines, air conditioners and other home appliances. Color-coated aluminum coils have a beautiful appearance and will not fade or change color. They can improve the grade and texture of home appliances and make home life better.

In terms of packaging, coated aluminum coils can be made into various forms of food, cosmetics and other packaging boxes to improve the quality and grade of the product. Welcome to leave message below to tell what you need.

Original source: https://www.hm-alu.com/a/what-are-aluminum-trim-coil-colors.html

没有评论:

发表评论