The 5000 series aluminum alloy has as good corrosion resistance and weldability. The tank body made of aluminum alloy can transport various liquids or liquefied gas without any protective coating inside, and because there is no corrosion, the oil quality is guaranteed.

Aluminum alloy has good electrical conductivity and rarely accumulates static electricity on the tank body, so sparks will not be generated and cause explosions, and aluminum alloy can well absorb the instantaneous capacity generated by the tank body when it collides.

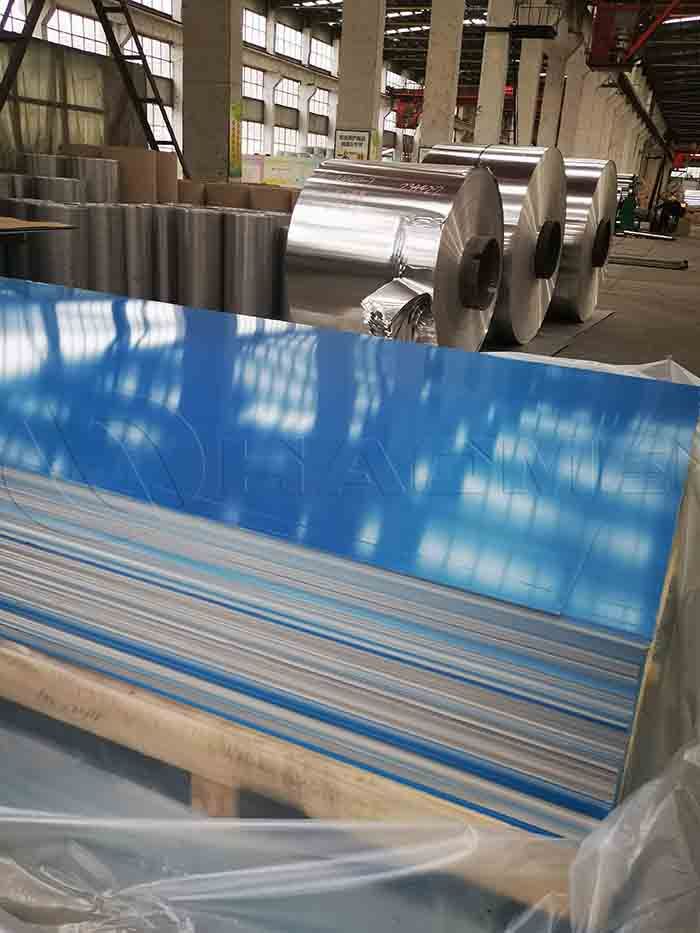

5083, 5754, 5454, 5059 and 5182 aluminium sheet are a common choice for making oil tankers and other chemical transport vehicles. They have the characteristics of large size, medium strength, high-quality surface, high formability, and has good corrosion resistance and welding performance, and recyclability. The toughness and strength of 5083-H321 aluminum alloy will increase at low temperature, which is very suitable for use in storage tanks of liquefied natural gas (LNG) in transport ships.

5182 aluminum plate for oil tanker is the latest high-magnesium alloy tanker specially designed for European dangerous goods road transport agreement in recent years. Its tensile strength and elongation are relatively high. When 5182 aluminum alloy is used for welding, the mechanical properties in welding can reach the minimum values specified for the base metal. The excellent quality of the 5182 alloy plate improves the safety of the aluminum alloy tanker.

What is the temperature 5182 aluminum alloy tank truck can undertake? It can withstand temperature up to 560 degrees Celsius. However, when the temperature exceeds 550 degrees Celsius, the tanker will basically become very brittle, soft, deformed, and have no bearing pressure.

Special requirements for aluminum alloy tank trucks

1. Process requirements

In addition to solving the requirements of special workshops, equipment, skilled personnel, supply of aluminum alloy materials and production technology, the production of aluminum alloy tank cars also requires a large amount of capital investment, especially the introduction of new production and processing technology for aluminum alloy tank cars.

2. Material requirements

At present, most manufacturers mainly use 5083 aluminum alloy plate as the material of the tank body, but the use of 5182 alloy can better reflect its corrosion resistance and welding performance, and under the same loading quality, the wall thickness of the tank body can be thinner and the weight is lighter.

Original source: https://www.aluminium-tanker-plate.com/a/a-better-choice-5182-aluminum-sheet-for-fuel-tank.html

没有评论:

发表评论