AW 7075 aluminium and 7068 aluminium alloy belong to the 7xxx aluminum alloy. The development of the 7xxx aluminum alloys began in the 1930s. It is an Al-Zn-Mg heat-treatable aluminum alloy with Zn as the main alloy element.

7075 aluminum alloy has high strength, low plasticity and toughness, and is sensitive to stress corrosion cracking. It is the most widely used 7xxx aviation aluminum alloy. The other 7xxxx aluminium alloys are basically developed on the basis of the 7075 aluminum sheet.

The main tempers of AW 7075 aluminum are O, T6, T651, T73 and T76. T6 temper has the highest static strength, the lowest plastic toughness, poor fatigue performance, and is sensitive to stress corrosion cracking, and its toughness decreases with the decrease of temperature, so the T6 temper is not used for low temperature working parts.

The T73 temper has the lowest strength, but has higher fracture toughness and excellent resistance to stress corrosion cracking and erosion. The performance of the T76 temper is between T6 and T73. Compared with the T6 state, its strength is low but the stress corrosion resistance is better. In comparison with T73, its strength is high but the stress corrosion resistance is poor.

7068 aluminum alloy is a new high-performance aluminum alloy. The typical yield strength reaches 700 MPa, which is 15% to 20% higher than 7075 alloy. The high temperature performance is better than 7075.

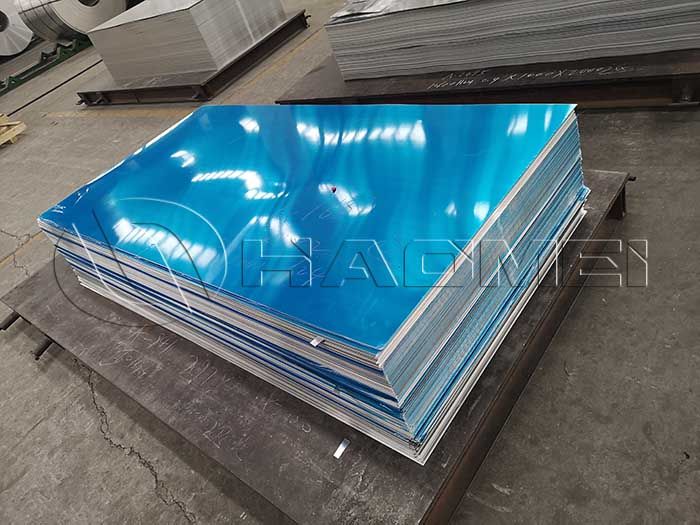

Due to its excellent properties, 7068 aluminum sheet has been adopted by the Federal Aviation Administration (FAA) and the National Aeronautics and Space Administration (NASA). Haomei Aluminum has both 7075 and 7068 aluminum. Welcome to leave message below to inquire what you need.

Original source: https://www.aircraftaluminium.com/a/aw-7075-aluminium-vs-7068-aluminium-alloy.html

没有评论:

发表评论