As a big aluminum alloy manufacturer, Haomei has rich kinds of aluminum strip and aluminum circle for different uses. We have thin flat aluminum strip for face mas, transformer winding, decoration,etc. We also have deep drawing aluminum circle and anodized aluminum discs for cookware and kitchenware. Welcome to get a quote by emailing us: dolly@alumhm.com or visit website: https://www.alumhm.com/aluminum-strip/

With 20 years'development, Haomei has grown into a top aluminium alloy manufacturers and suppliers. We have comprehensive kinds of aluminium sheets, aluminum coil, aluminum strip, aluminum foil, aluminum discs, aluminum tread plate, color coated aluminum and CTP plates, covering series-1, series-3,series-5, series-6 and series-8. You can realize one-stop purchase in Haomei.

What Is The Pharmaceutical Aluminium Foil Specification?

The pharmaceutical aluminum foil first appeared in some European countries in the 1930s. China first began to adopt foreign technology and imported foreign equipment and raw materials in the 1980s. Now it has got rapid development.

There are strict requirements for on the quality of medicinal aluminum foil. The appearance of the surface must be kept clean and evenly coated; the text and pattern printed on it must be correct, clear and firm, and there must be no dense and continuous holes.

As an aluminium foil jumbo roll manufacturer, Haomei Aluminum offers different alloys of aluminum foil for pharmaceutical packaging. There is the pharmaceutical aluminium foil specification:

Type

|

Typical alloy

|

Temper

|

Thickness

|

Width

|

Application

|

8011

|

O, H18

|

0.016-0.5

|

100-1600

|

capsule medicine cover

| |

Aluminium blister foil

|

8021

|

O

|

0.04-0.065

|

100-1600

|

Blister packaging

|

Tropical medicinal aluminum foil

|

8021,8079

|

O

|

0.016-0.2

|

100-1600

|

High-end pharmaceutical packaging

|

Aluminum foil for bottle cap

|

8011

|

H14,H16

|

0.016-0.5

|

100-1600

|

Oral liquid aluminum-plastic composite cover, infusion bottle aluminum-plastic cover,etc.

|

The advantages of Haomei aluminum foil jumbo roll:

- It features clean surface, uniform color, no spot and no holes.

- It is non-toxic, tasteless and safe.

- It is of strong mechanical properties, high blast resistance, strong puncture and tear resistance.

- It can follow these executable standards: national standard, American standard, European standard, Russian standard, Japanese standard, etc.

Pharmaceutical Aluminium Foil Specification

At present, it is more and more common to use blister packaging in the packaging of health food and pharmaceutical tablets and capsules. PTP alumium foil is the sealing material on the medicinal PVC sheet.

Almost all products that require opaque or high-barrier composite materials in modern packaging use aluminum foil as the barrier layer. This is because aluminum foil has a highly dense metal crystal structure that can completely block any gas. What is the pharmaceutical aluminium foil specification?

There are different forms of aluminum foils for pharmaceutical packaging:

PTP foil: it is also called medicinal plate aluminum foil and capsule aluminum foil. It is mostly made of 8011-H18 aluminum foil or 8011-O aluminum foil with thickness of 0.016-0.04 mm.

Blister foil: It is also called cold-formed medicinal foil, is mostly made of 8021-O aluminum foil. It is used for high-end and tightly sealed drug packaging with moisture-proof and light-shielding. The thickness is 0.04-0.065 mm.

Tropical type medicinal aluminum foil: It is also called aluminum-plastic aluminum, which is equivalent to adding a layer of cold stamping aluminum foil outer cover on the outside of the plastic blister and PTP aluminum foil. 8021-O aluminum foil and 8079-O aluminum foil are mostly used, which is the highest-end packaging aluminum foil in pharmaceutical packaging.

Aluminum foil for drug bottle caps: Aluminum foil for drug bottle caps is also called aluminum foil for medical cap materials. It is mostly made of 8011-H14 aluminum foil or 8011-H16 aluminum foil. It is widely used in bottled liquids such as pharmaceutical oral liquids, antibiotics, and infusions.

As an aluminum foil jumbo roll manufacturer, Haomei Aluminum has all the above mentioned aluminum foil. Welcome to leave message to inquire what you need directly.

What Is 7075 Aluminum Plate

The 7075 aluminum plate is an important aircraft aluminium sheet. It is an aluminum-magnesium-zinc-copper alloy and a heat-treatable alloy. It is a super hard aluminum alloy and has good wear resistance. After further processing, it doesn’t have deformation.

Of this alloy, the 7075 T6 aluminum plate is a top grade and it is known as the best product among aluminum alloys with high strength. This alloy also has good mechanical properties and anodizing reaction.

Zinc is the main alloying element in 7075 aluminum sheet. Adding magnesium to the 7075 aluminum alloy containing 3%-7.5% zinc can form MgZn2 with a significant strengthening effect, making the alloy's heat treatment effect far better than aluminum-zinc aluminum alloys. Increasing the content of zinc and magnesium in the alloy will further improve the tensile strength, but its resistance to stress corrosion and spalling corrosion will decrease.

The 7075 aluminum plate is mainly used to manufacture aircraft structures and other high-stress structural parts that require high strength and corrosion resistance, such as aircraft upper and lower wing panels, stringers, etc. It is also widely used in mold processing, mechanical equipment, phone shell,etc.

After solution treatment, 7075 aluminium sheet has good plasticity and good heat treatment strengthening effect. It also has good strength below 150 degrees, and has particularly good low temperature strength, poor welding performance, and stress corrosion cracking tendency.

As a big 7075 aluminium plate supplier, Haomei 7075 aluminum plate has internal stress relief and no deformation when cutting. The maximum width is 2600mm and the maximum thickness is 200mm.

All of our 7075 aluminum plate is rolled by the ultra-wide 2650mm German SMS cold rolling mill, which has better shape, higher precision and more stable performance. All the super wide 7075 aluminum alloy plates produced by Haomei are ultrasonically detected, which can effectively ensure that there are no blisters and impurities.

Original source: https://www.hm-alu.com/a/what-is-7075-aluminum-plate.html

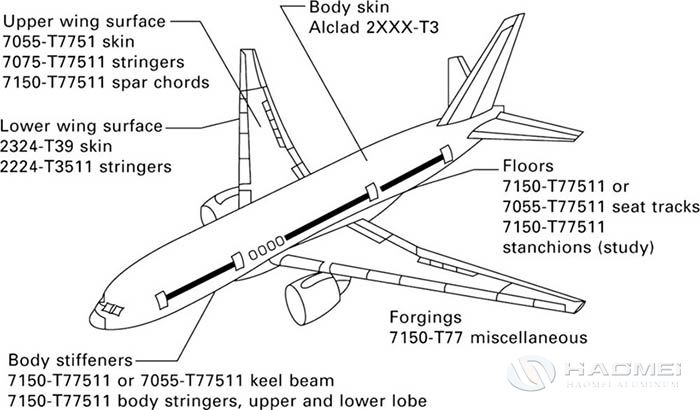

The Main Kinds of Aircraft Aluminium Sheets

In 1906, German Wilm accidentally discovered that after a certain period of time at room temperature, the strength of aluminum alloy would gradually increase with the prolonged storage time. This phenomenon was later referred to as age hardening, and as one of the earliest core technologies to promote the development of the aircraft aluminum sheets.

In the following hundred years, aircraft aluminum sheet manufacturers has made many research on aluminum alloy composition and synthesis methods, and the aluminum alloy processing technology such as rolling, extrusion, forging, heat treatment,etc.

The aircraft aluminum plate has the advantages of high strength, good processing and formability, low cost and good maintainability. It is widely used in aircraft main structure materials. The improvement of the aircraft properties such as flight speed and structural weight reduction put forwards higher requirements for the aluminum alloys.

There are four main kinds of aircraft aluminum alloys: 2024,7075,7050 and 6061 aluminum sheet. 2024 aluminium sheet has high fracture toughness and low fatigue crack growth rate. It is the most commonly used aircraft fuselage and underwing material.

7075 aluminum plate was successfully developed in 1943. It was successfully applied to the B-29 bomber. The strength of 7075-T6 aluminum alloy is the highest, but but its resistance to stress corrosion is poor.

7050 aluminum plate is developed on the basis of 7075 aluminum alloy, which has better strength, anti-flaking corrosion and stress corrosion resistance, and is applied to the compression components of F-18 aircraft.

6061 aluminum sheet can also be used on the aircraft. It has good corrosion resistance and excellent welding performance, but the strength is moderately low.

订阅:

评论 (Atom)

Color Aluminum Strip for Ceiling

In interior decoration, suspended ceilings not only impact the overall visual effect but also their practicality and durability. Nowadays,...

-

The plate used in the CTF process is mainly PS plate , which is pre-coated photosensitive plate, which is developed to adapt to the rapi...

-

With the spread of energy saving and emission reduction concept, lightweight vehicles have been quickly promoted. Aluminum alloy is one of...

-

In the vast world of aluminum alloys, 5052 and 5754 aluminum alloys have become effective materials in many fields due to their unique pro...