Facing to the spread of COVID-19, face masks have become an effective measure to protect ourselves. To better fit our face, we need nose bridge strip. There are mainly two kinds: plastic nose wire and aluminum nose wire. What are their differences?

Raw Material

Plastic nose wire is made of polyolefin polymer and can be bent and deformed like a metal wire under the action of external force. After losing the external force, the shape remains unchanged and does not rebound. The production cost is relatively low.

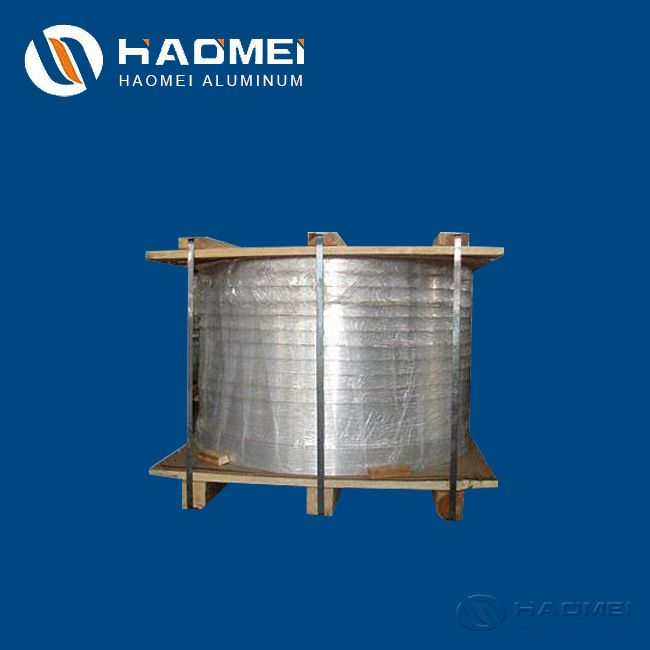

Aluminum nose wire is made from thin aluminum strip. The commonly used is 1060 and 3003 aluminum strip. Its width is 90-100 mm. Thickness is 0.4*0.5 mm. The requirements for aluminum strip for face mask is of great rust resistance, corrosion resistance, high brightness, good straightness, no deformation, stable size, high strength, good toughness and good combination with glue.

Mask Types

Plastic nose wire is of light-weight and have good shaping effects, which is suitable for disposable masks and medical Masks. Because of better performance and better shaping effect, aluminum nose wire is is suitable for masks being worn for a long time. It is mainly used for N95 and KN95 masks.

Environmental Protection

Since aluminum nose wire has close combination with non-woven material are mixed together, it is difficult to separate and recycle them. All plastic nose bridges are made of polyolefin. Polypropylene and polyethylene are important materials in polyolefins. It can be recycled.

Haomei Aluminum is the upstream enterprises of aluminum nose wire manufacturers. We can provide 1060 and 3003 aluminum strip for face mask. If you need, we will give you the best price.

Original source: https://www.alumhm.com/a/plastic-nose-wire-v-aluminum-nose-wire.html

没有评论:

发表评论