In the world of wine packaging, wine bottle caps made of aluminum foil are gradually becoming the first choice of many wine brands with their unique advantages.

One of the biggest advantages of aluminum foil wine bottle caps is its excellent sealing. Aluminum foil is soft and has excellent ductility. It can fit tightly to the bottle mouth, forming a solid barrier, effectively preventing air and moisture from entering the bottle and preventing the wine from oxidizing and deteriorating.

This feature is especially important for wine. Wine is extremely sensitive to the storage environment, and a trace of oxygen entering may cause changes in its flavor and taste. Aluminum foil wine bottle caps can keep the freshness and fruity aroma of wine for a long time, allowing consumers to still taste the wonderful taste of the wine when opening the bottle.

In addition, spirits such as whiskey and brandy also need good sealing to maintain their alcohol content and aroma during storage. Aluminum foil wine bottle caps can also perform this task well to prevent the quality of spirits from being reduced due to volatilization.

In addition to sealing, aluminum foil wine bottle caps also have good moisture resistance. For some wines that need to be stored for a long time, such as aged liquor, a humid environment may affect the quality of the wine and even cause damage to the packaging. Aluminum foil material can effectively resist moisture and provide a dry storage environment for the wine, ensuring that the quality of the wine is not affected during storage and becomes more mellow over time.

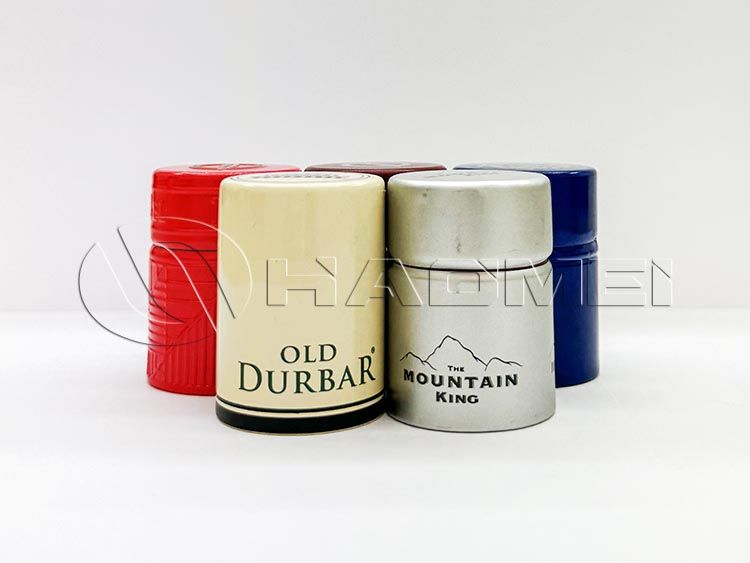

From the perspective of aesthetics and marketing, aluminum foil wine bottle caps also have a unique charm. Aluminum foil can be decorated in a variety of ways through printing, hot stamping and other processes, presenting a gorgeous and exquisite appearance. Whether it is a simple and atmospheric design or an artistic pattern, it can be perfectly displayed on the aluminum foil wine bottle cap.

This exquisite packaging can enhance the grade and brand image of the wine and attract the attention of consumers. For some high-end wines, such as fine wines, limited edition spirits, etc., the exquisite appearance of the aluminum foil wine bottle cap complements the high quality of the wine, satisfying consumers' dual pursuit of product appearance and quality.

In addition, the aluminum foil wine bottle cap also has environmental advantages. Aluminum is a recyclable metal material with low energy consumption during the recycling process and is environmentally friendly. In the context of increasing environmental awareness among consumers today, whiskey bottle caps using aluminum can gain more favor from consumers and conform to the concept of sustainable development.

Original source: https://www.alubottlecaps.com/a/what-are-benefits-of-aluminum-foil-wine-bottle-caps.html