With 20 years'development, Haomei has grown into a top aluminium alloy manufacturers and suppliers. We have comprehensive kinds of aluminium sheets, aluminum coil, aluminum strip, aluminum foil, aluminum discs, aluminum tread plate, color coated aluminum and CTP plates, covering series-1, series-3,series-5, series-6 and series-8. You can realize one-stop purchase in Haomei.

How Fast Is An Aluminum Bottle Cap Produced #factory #packaging #bottlecaps

Thin VS Thick Aircraft Aluminum Sheet

Thin aluminium sheet

It refers to aluminum sheets with a thickness between 0.2mm and 6.0mm. Its biggest advantage is its lightness, which is of great significance to the aviation industry, which pursues lightweight to reduce energy consumption and improve flight performance.

In aircraft manufacturing, the thin aluminum sheet is mainly used for the skin of the fuselage and wings. As the "outer coat" of the aircraft, the fuselage skin is directly subjected to air flow friction and external environmental erosion. With good formability, the thin sheet can perfectly fit the complex curved surface of the fuselage, create a smooth aerodynamic shape, and reduce flight resistance.

Common passenger aircraft such as Boeing 737 and Airbus A320 use a large amount of 2024 thin aluminum sheets for the fuselage skin. It is not only light in weight, but also has high strength and fatigue resistance, ensuring the structural integrity of the fuselage during frequent takeoffs and landings and long-term flights.

The wing skin is also critical, as it needs to withstand complex stresses such as bending and torsion during flight. 7075 aluminum alloy sheets are often used for the upper and lower skins of the wing due to their high strength and good toughness. For example, on some high-performance fighters, the wing skins are made of 7075-T6 sheets, which reduce weight while ensuring the structural strength of the wing, thereby improving the maneuverability and fuel efficiency of the aircraft.

In addition, some structural parts inside the aircraft, such as cabin partitions and ceilings, also use aluminum alloy thin plates. Although these parts do not bear the main load, they are sensitive to weight. Thin plates can effectively control the overall weight of the aircraft on the basis of meeting structural requirements.

In addition, the good conductivity and processability of thin plates make it also have a place in the manufacture of shells for avionics equipment. It can not only provide protection for the equipment, but also facilitate electromagnetic shielding and ensure the stable operation of electronic equipment.

Thick aluminium sheet

The thickness of the thick aluminium sheet is generally above 6.0mm. Unlike the lightness of thin plates, it has a strong load-bearing capacity and becomes a solid "skeleton" of aviation structures. In aircraft manufacturing, thick plates are mainly used to manufacture key components that bear high loads. For example, the wing beam of an aircraft, as the main load-bearing structure of the wing, needs to withstand huge bending and shear forces.

7050 aluminum alloy thick plate has the characteristics of high strength, high toughness, fatigue resistance, and damage resistance, and is an ideal material for manufacturing wing beams. The wing beams of the C919 large passenger aircraft use 7050 aluminum alloy thick plates. Through advanced processing technology, the wing beams are ensured to have sufficient strength and stability to support the entire wing and the huge load of the aircraft during flight.

The fuselage frame is also inseparable from thick plates, which are like human bones and provide overall structural support for the aircraft. 2219 thick aluminum plates are often used to manufacture fuselage frames because of their good welding performance and comprehensive mechanical properties. On large transport aircraft, the fuselage frame is welded with 2219 aluminum thick plates to build a solid fuselage structure to ensure that the aircraft can withstand the internal pressure of the fuselage and the external complex environmental stress when carrying cargo and passengers.

Some parts of the aircraft engine, such as mounting seats and load-bearing rings, are also made of aluminum alloy thick plates. The engine will generate huge thrust and vibration when working. These parts need to have extremely high strength and fatigue resistance. Thick plate materials can meet this stringent requirement and ensure stable and reliable operation of the engine.

Original source: https://www.aircraft-aluminium-sheet.com/a/thin-vs-thick-aircraft-aluminum-sheet.html

The Use of 6016 and 6101 Aluminum in Car Making

6016 aluminum sheet

6016 aluminum alloy is an Al-Mg-Si-Cu alloy developed by Alcoa. It has good fracture toughness, corrosion resistance and fatigue-relieving properties, especially excellent in forming performance, so it is widely used in the automotive field.

The outer plate of automobile covering parts is an important application direction of en aw 6016. 6016 aluminum alloy sheets are often used in parts such as automobile hoods, doors, truck lids, and roofs. Taking the outer plate of the automobile hood as an example, it not only affects the appearance and aerodynamic performance of the vehicle, but also needs to take into account lightweight, safety and manufacturing process feasibility.

6016 aluminum alloy has significant advantages in this regard. Its elongation can reach 22-25%, which is much higher than the 15-20% of ordinary steel. This allows it to stamp out complex streamlined shapes such as engine hoods. Moreover, it has a small rebound after stamping, with a rebound angle of about 3-5°, which can effectively reduce dimensional deviation and ensure assembly accuracy.

At the same time, the surface of 6016 aluminum alloy is smooth and has no orange peel after spraying. It has good corrosion resistance due to the natural oxide film and is not easy to rust after long-term use.

In terms of manufacturing process, 6016 aluminum alloy sheets need to go through solid solution treatment, pre-aging treatment (T4P) and baking varnish treatment. After such process treatment, 6016 aluminum alloy sheets can have good forming properties before stamping, and can quickly increase strength during the baking varnish process after stamping, and have high dent resistance.

European automakers generally use 6016 aluminum alloy plates for body panels, and their good forming properties are fully utilized. In recent years, with the increasing demand for lightweight in the domestic automobile industry, domestic companies are also actively researching and applying 6016 aluminum alloys.

6101 aluminum sheet

6101 aluminum alloy belongs to the low-alloyed Al-Mg-Si conductive aluminum alloy, which has high specific strength, good conductivity, corrosion resistance and formability, and has specific application scenarios in the automotive field.

In the conductive system of the car, 6101 aluminum alloy is very useful. For example, the power battery busbar, battery connection plate and other components of new energy vehicles are often made of high-conductivity aluminum alloys such as 6101.

Take the power battery busbar as an example. It is a key component that connects the battery module and the battery management system, and has extremely high conductivity requirements. The high conductivity of 6101 aluminum alloy can reduce resistance, improve energy conversion efficiency, and make the battery charge and discharge performance better, thereby improving the overall performance of new energy vehicles.

In terms of manufacturing process, the processing flow of 6101 aluminum alloy is generally casting - rolling - solution treatment - cold drawing - aging heat treatment. Through such a process, 6101 aluminum alloy can have higher strength and meet the comprehensive requirements of automotive parts in terms of strength and conductivity.

Original source: https://www.aluminium-auto-sheet.com/a/the-use-of-6016-and-6101-aluminum-in-car-making.html

What Are Uses of Aluminum Clad Steel in Shipbuilding

In the main structure of the ship, such as the hull, deck and other parts, aluminum clad steel plates are gradually showing their value. In this structure, the steel plate provides high strength and good impact resistance, and can withstand external forces such as waves and collisions during the voyage of the ship. The aluminum plate gives the ship the advantage of lightweight, reduces the overall weight of the ship, and thus improves fuel economy and reduces operating costs. By combining steel and aluminum plates, the strengths of both are brought into play, effectively improving the comprehensive performance of the ship structure.

In terms of specifications, the thickness of the steel-aluminum composite plate used for ship structures is usually within a certain range to ensure structural strength, such as the common range of 3-8 mm; the thickness of the aluminum plate layer is generally around 2-5 mm according to specific needs. Such a thickness combination not only meets the requirements of the ship for structural strength, but also achieves a good lightweight effect.

The superstructure of the ship, such as the cab, cabin and other areas, has high requirements for the weight, aesthetics and corrosion resistance of the material, and the steel-aluminum composite plate can just meet these requirements. For example, some inland tourist sightseeing boats have aluminum alloy structures for their superstructures, which are connected to the steel structure of the main hull through steel-aluminum composite joints.

The aluminum alloy part (that is, the aluminum layer in the steel-aluminum composite plate) reduces the weight of the superstructure, lowers the center of gravity of the ship, and improves navigation stability; at the same time, the good corrosion resistance of aluminum alloy can adapt to the long-term use of ships in humid environments and reduce maintenance costs. Moreover, after the surface of the aluminum alloy is treated, it has good aesthetics and improves the overall image of the ship.

In terms of specifications, the aluminum layer of the steel-aluminum composite plate used for the superstructure is relatively thin, generally 1-3 mm, to further reduce the weight; the thickness of the steel layer is about 2-4 mm, which is used to provide the necessary strength support. This light and thin structural design minimizes the weight while meeting the functional requirements of the superstructure.

With the development of the application of new energy in the field of ships, steel-aluminum composite plates have also found their place in the power system of new energy ships. In the battery box, steel-aluminum composite plates can play an important role. The steel plate layer provides high-strength protection to prevent the battery box from being damaged by external impact; the aluminum plate layer, due to its good electrical and thermal conductivity, helps the heat dissipation management of the battery, ensures that the battery works at a suitable temperature, and improves battery performance and service life.

From the specifications, the aluminum cladding panel size used in the battery box generally has a steel plate layer thickness of 1-3 mm and an aluminum plate layer thickness of about 1-2 mm. Such thickness can meet the protection requirements for the battery without adding too much weight to the battery system.

Original source: https://www.marine-aluminium-plate.com/a/what-are-uses-of-aluminum-clad-steel-in-shipbuilding.html

The Uses of Aluminum 5083 and 5454 in Special Vehicles

In the field of modern logistics and transportation, various types of special vehicles play a key role. The rise of aluminum alloys has brought revolutionary changes to these special vehicles. In particular, 5083 and 5454 aluminum alloys, with their unique properties, have occupied an important position in vehicle manufacturing.

Aluminum alloy in vans

As a common vehicle type for logistics transportation, vans have high requirements for the strength, weight and durability of the body. The application of aluminum alloy perfectly meets these requirements. In developed countries such as Europe, the United States, Japan and South Korea, aluminum alloy vans have long been widely popularized, and foreign aluminum vans account for as much as 64.6% of the overall truck market.

In the manufacture of vans, 5083 aluminum alloy like aluminum 5083 h32 has been widely used. It has medium strength, a magnesium content between 4.0% and 4.9%, and excellent welding performance, which makes the assembly of the van more solid and reliable. Its excellent corrosion resistance can effectively resist the erosion of various environmental factors during transportation.

Aluminum alloy in refrigerated trucks

Refrigerated trucks are mainly used to transport temperature-sensitive goods, such as food and medicine. The body structure needs to have good thermal insulation and lightweight characteristics to ensure the quality of goods and reduce energy consumption. Aluminum alloy has been widely used in the field of refrigerated trucks due to its advantages such as low density, high strength and good corrosion resistance. Aluminum alloy can be seen from the frame, roof to side panels.

In the application scenarios of refrigerated trucks, 5083 aluminum alloy also performs well. Its high strength can withstand the weight of refrigerated equipment and cargo, ensuring the safety of the vehicle during driving.

At the same time, 5454 aluminum alloy is also used in some parts of refrigerated trucks. Its high strength and corrosion resistance provide a guarantee for the long-term stable operation of refrigerated trucks.

Aluminum alloy in fuel tanks

The oil products transported by tank trucks are flammable and explosive dangerous goods, so the safety, lightweight and corrosion resistance of the vehicles are extremely high. Aluminum alloy tank trucks have obvious advantages over traditional carbon steel, stainless steel and other materials.

In the manufacture of tank bodies of oil tank trucks, 5083 aluminum alloy is one of the commonly used materials. It has high hardness, strong corrosion resistance, and good weldability, which can ensure the sealing and strength of the tank body and meet the needs of long-term transportation of oil products by oil tank trucks.

For example, the 5083 aluminum plate produced by Haomei Aluminum has stable performance by optimizing the melting and casting process and rolling technology. It can produce ultra-wide aluminum plates with a width of up to 2650mm and a thickness of 0.3-500mm, which meets the material standards of tank trucks and is widely used in the tank body, head and baffles.

5454 aluminum alloy is often used in the internal baffles of oil tankers because of its strong corrosion resistance and strength that is about 20% higher than 5052. It is suitable for high temperature or harsh environments. It improves the structural stability of the tank, prevents liquid sloshing, and ensures driving safety.

Aluminum alloy in powder tank trucks

Powder tank trucks are mainly used to transport powdered materials such as cement, fly ash, and lime powder. As the market's requirements for transportation efficiency and cost control continue to increase, lightweight has become an important trend in the development of powder tank trucks. The application of aluminum alloy in powder tank trucks effectively achieves the goal of lightweight vehicles.

In the manufacture of powder tank trucks, 5083 aluminum alloy provides reliable structural support for the tank body with its strength and welding performance. At the same time, some manufacturers will also choose materials such as 5454 h32 aluminum sheet according to actual needs to meet the use requirements of powder tank trucks under different working conditions.

Original source: https://www.aluminium-tanker-plate.com/a/the-uses-of-aluminum-5083-and-5454-in-special-vehicles.html

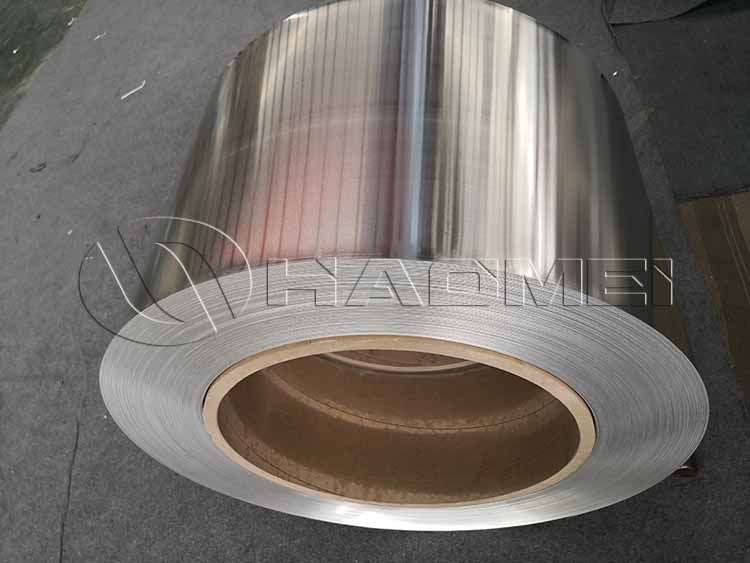

How to Choose The Aluminum Strip Width

In the cost control and efficiency improvement of industrial production, the selection of aluminum strip width plays a key role. Choosing the right width can not only avoid material waste, reduce procurement costs, but also reduce energy consumption and working hours in the processing link. On the contrary, improper width may lead to excess materials, redundant processes, and even affect product performance.

The width of aluminum strips spans a wide range to meet the diverse needs of different industries and applications. Common aluminum strip widths (in inches) include but are not limited to: 1/4 inch, 1/2 inch, 1 inch, 2 inches, 4 inches, 6 inches, 8 inches, 12 inches, etc. Of course, non-standard widths can also be customized according to customers' special requirements in actual production.

1/4-inch aluminum strip

1 4 inch aluminum strips are commonly used in some electronic devices with strict space requirements and low current load. For example, in the winding production of small transformers, the 1/4-inch aluminum strip can be tightly wound, effectively utilize space, and achieve efficient electromagnetic conversion.

Its narrow width helps to achieve fine wiring in a limited space, while meeting the needs of low current transmission, reducing the heat generated by excessive current density, and improving the stability and service life of the transformer. From a cost perspective, replacing wide aluminum strip with narrow strips can avoid material waste and reduce the material cost per unit product.

12 inch aluminum strip

12 inch wide aluminum strips are mostly used in large-scale power transmission and industrial manufacturing. In the production of busbars in the power industry, 12-inch aluminum strips can carry huge currents because their large cross-sectional area can effectively reduce resistance and reduce the loss of electricity during transmission - this not only improves energy efficiency, but also reduces the maintenance cost of equipment due to overheating.

In the manufacture of heat sinks for large industrial equipment, the large heat dissipation area provided by wide aluminum strips can reduce the investment in additional cooling devices, indirectly saving energy consumption for enterprises.

How to choose aluminum strip width

Current carrying capacity

If the application scenario involves current transmission, such as transformer windings, busbars, etc., the width of the aluminum strips for sale is one of the key factors affecting the current carrying capacity.

According to Ampere's law, when current passes through a conductor, heat is generated. The larger the cross-sectional area of the conductor, the greater the current it can carry and the less heat it generates. Therefore, the selection of width that matches the current demand is the core of balancing cost and performance.

Space limitations

In applications with strict space requirements such as electronic devices and small machinery, the width of the aluminum strip must match the available space. For example, in electronic products with compact internal structures such as smartphones and laptops, only narrow width aluminum strips can be used.

Mechanical performance requirements

Aluminum strips of different widths also have different mechanical properties. Wider aluminum strips usually show better stability and strength when subjected to external forces such as stretching and bending, and are suitable for occasions that require higher mechanical strength, such as the reinforcement of building curtain walls.

Narrow aluminum strips have more advantages in flexibility and are suitable for applications that require frequent bending or curling, such as the flexible circuit connection parts in some wearable devices.

Original source: https://www.aluminumstrip24.com/news/how-to-choose-the-aluminum-strip-width.html

What Are Differences of 5454 and 5083 Aluminum in Tanker Manufacturing

5454 aluminum plate belongs to aluminum-magnesium alloy with medium strength. Its outstanding feature is good corrosion resistance, which can effectively resist corrosion in various environments, which provides reliable protection for tank trucks to transport various liquid or powder materials, and can prevent safety hazards such as leakage caused by corrosion of the tank body. 5454 h32 aluminum sheet is its main temper.

5083 aluminum plate is also a member of the aluminum-magnesium alloy family, but it is different from 5454 in terms of performance focus. It has high strength and can withstand greater pressure and weight, which makes it popular in large tank trucks and applications with strict requirements on tank strength. Its excellent fatigue resistance can effectively resist fatigue damage caused by vibration and bumps in long-term and frequent transportation operations, and extend the service life of the tank truck. The toughness of 5083 aluminum plate is also very outstanding. It is not easy to break when encountering collisions or external impacts, which greatly improves the safety of tank trucks during transportation. Although it has good corrosion resistance, it may be slightly inferior to 5454 in some special corrosive environments.

Market share analysis

In the current tank truck manufacturing market, 5083 aluminum plate occupies a large market share due to its high strength and good comprehensive performance. Especially in the field of heavy tank trucks, such as the manufacture of large oil tank trucks and tank trucks for transporting crude oil, chemical raw materials, etc., 5083 aluminum plate for tanker body is more widely used, accounting for about 60% of the tank truck aluminum plate market share.

This is mainly due to its ability to meet the strict requirements of heavy tank trucks for tank strength and safety, and at the same time, the cost-effectiveness is also considerable in large-scale production.

5454 aluminum plate performs well in some tank truck market segments that have extremely high requirements for corrosion resistance and relatively less extreme strength requirements, such as food-grade liquid transport tank trucks and some small chemical transport tank trucks. Its market share accounts for about 30% of the tank truck aluminum plate market. With the continuous improvement of food and chemical transportation safety standards, 5454 aluminum plate has a gradually increasing market share due to its excellent corrosion resistance.

Differences in tank truck application scenarios

5454 aluminum sheet is often used to manufacture tank trucks for transporting food-grade liquids (such as edible oil, beverage slurry, etc.). Due to its good corrosion resistance, it can ensure that the tank body will not pollute the transported food-grade liquid and ensure food safety. It is also common in some small chemical transport tank trucks. These chemicals may be corrosive to a certain extent. The corrosion resistance of 5454 aluminum sheet can effectively deal with it. At the same time, its good processability makes it easy to manufacture small and complex tank bodies.

Aluminum 5083 h32 is the absolute main force in the field of large oil tankers. For example, the tanks of common road tankers for transporting crude oil are mostly made of 5083 aluminum sheet. It is also widely used in large chemical liquid tankers. Such tankers need to transport a large amount of corrosive chemical raw materials. The high strength and good corrosion resistance of 5083 aluminum sheet can meet its safety needs during long-distance and heavy-load transportation.

In some large powder and particle transport tankers (such as cement transport tankers), 5083 aluminum sheet can withstand the impact and vibration during material loading and unloading with its high strength and fatigue resistance, ensuring the structural stability of the tank.

Original Source:https://www.aluminumtankerplate.com/a/what-are-differences-of-5454-and-5083-aluminum-in-tanker-manufacturing.html

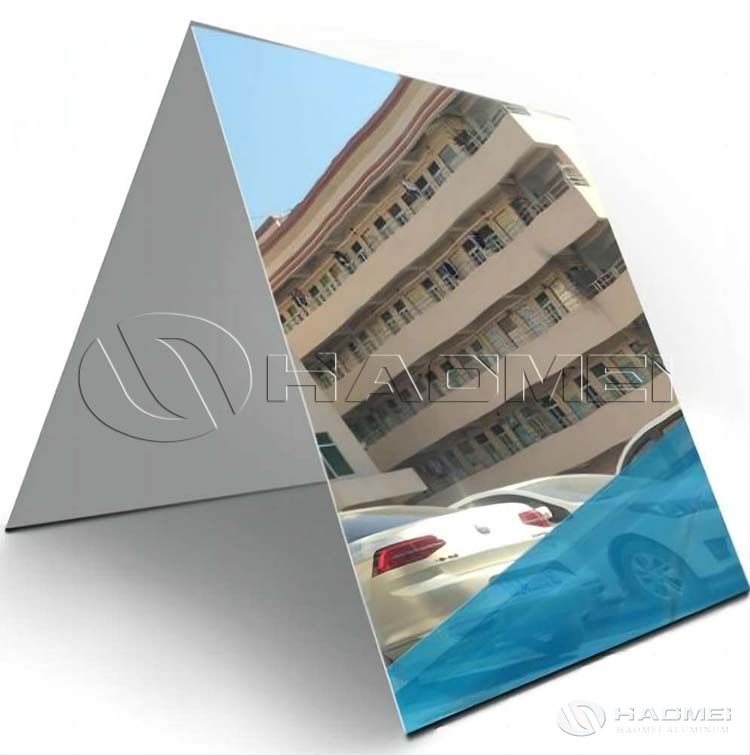

Aluminum Reflector Sheet for Floodlight

In outdoor lighting, stage lighting and other scenes, floodlights occupy an important position with their large-area lighting effects. In the construction of floodlights, the aluminum light reflector sheet occupies an important position, which directly affects the lighting efficiency and service life of floodlights. So, what are the specific requirements of floodlights for mirror aluminum plates?

Extremely high reflectivity is the core requirement of floodlights for mirror polished aluminum sheets. The working principle of floodlights is to emit light through the light source, and then reflect it through the mirror aluminum sheet, so as to achieve large-area lighting.

If the reflectivity of the mirror aluminum plate is not enough, a large amount of light will be absorbed or scattered, resulting in a significant reduction in the lighting effect. The reflectivity of high-quality reflective aluminum plates can usually reach more than 85%, and some high-end products can even exceed 90%, so that the energy of the light source can be converted into effective lighting to the maximum extent.

Good weather resistance is also essential. Floodlights are mostly used outdoors and need to withstand the test of various harsh environments such as wind, sun, and rain. If the mirror aluminum plate has poor weather resistance, it is easy to oxidize, corrode, discolor, and other problems during long-term use, which will affect the reflective effect.

Therefore, the surface of the mirror aluminum plate is usually specially treated, such as coating a protective film or anodizing, to enhance its corrosion resistance and UV resistance, and ensure stable performance under various climatic conditions.

High flatness is also critical. The surface flatness of the polished aluminum sheet will directly affect the reflection direction of the light. If the surface is not flat, the light will be scattered in a disorderly manner when reflected, and it will not be able to form a concentrated and uniform lighting area. This requires the mirror aluminum plate to strictly control the flatness during the production process to avoid defects such as bumps and wrinkles, and ensure that the light can be evenly reflected at the designed angle.

In addition, the appropriate thickness and strength also need to be considered. The aluminum mirror sheet needs to have a certain thickness and strength to ensure that it is not easy to deform during installation and use.

If the aluminum sheets for sale are too thin or insufficiently strong, they are easy to bend when subjected to external force, thereby changing the reflection angle and affecting the lighting effect. At the same time, the appropriate thickness can also enhance the heat dissipation performance of the aluminum plate, because the floodlight will generate a certain amount of heat when working, and good heat dissipation helps to extend the service life of the light source and the aluminum plate.

The last but not the least, excellent processing performance is also important. Floodlights come in a variety of shapes. In order to meet different design requirements, the reflective aluminum mirror sheet needs to be able to undergo a variety of processing operations such as cutting, bending, and stamping. If the processing performance is poor, it will be difficult to produce parts that meet the structural requirements of floodlights, increasing production difficulty and cost. Homei Alumnium provide such aluminum mirror sheet. Welcome to leave message below to tell us your need.

Original source: https://www.hm-alu.com/a/aluminum-reflector-sheet-for-floodlight.htmlre

7075 T351 VS T4

7075 aluminum plate belongs to the Al-Zn-Mg-Cu series of super-hard aluminum. It has been used in the aircraft manufacturing industry since the late 1940s and still occupies an important position in the aviation industry and other fields.

7075 T351

Performance Characteristics

High Strength and Good Toughness: AA7075 t7351 has high strength, with tensile strength typically reaching a certain level, meeting numerous strength-demanding applications. It also possesses excellent toughness, resisting brittle fracture when subjected to significant external impact, maintaining structural integrity.

Excellent Machinability: This aluminum alloy exhibits excellent machinability. Both cold and hot working processes can be performed smoothly. For example, during machining, it can be precisely machined into various complex shapes through turning, milling, and drilling, resulting in excellent surface quality. This is due to its uniform microstructure and moderate hardness.

Excellent Corrosion Resistance: 7075 T351 exhibits excellent corrosion resistance under normal conditions. The combination of its alloying elements and heat treatment process allows it to form a dense oxide film on its surface. This film effectively blocks the intrusion of corrosive media, protecting the metal within and extending the service life of components.

Stress relief properties: The T351 state means that the material has been pre-stretched to eliminate internal stress. This greatly improves the dimensional stability of the material during subsequent use, and it is not easy to deform due to the release of internal stress, which is crucial for some applications that require extremely high dimensional accuracy.

Application fields

Aerospace field: In aerospace fixtures, 7075 T351 aluminum alloy is widely used. Many parts of aircraft, such as wing structures and fuselage frames, are made of 7075 T351 aluminum alloy. These parts need to have high strength to withstand various complex stresses during flight, and good toughness can prevent brittle failure in harsh environments such as high altitude and low temperature. Its excellent processing performance can meet the processing requirements of complex shapes of aviation parts, and the stress relief characteristics ensure the dimensional stability of parts during long-term use, ensuring flight safety.

High-end machinery manufacturing: In the manufacturing of high-end machinery and equipment, such as key parts of precision machine tools and structural parts of industrial robots, 7075 T351 aluminum alloy is also often used. Machine tool components require high precision and stability, and the performance of 7075 T351 aluminum alloy precisely meets these requirements, ensuring that machine tools maintain accuracy during high-speed operation and long processing times. Industrial robot structural components must maintain sufficient strength while minimizing weight to enhance mobility and energy efficiency. The high strength and relatively light weight of 7075 T351 aluminum alloy make it an ideal choice.

7075 T4 aluminum

Performance characteristics

High strength and good plasticity: The aluminum alloy in the 7075 T4 temper has high strength. Although the strength value may be slightly different from that of T351, it can still meet the strength requirements of many engineering applications. At the same time, it has good plasticity after solution treatment, which allows the material to be processed into various complex shapes through forging, extrusion, stretching and other processes during the forming process, and it is not easy to have defects such as cracks during the processing.

Good mechanical properties: The aluminum alloy in this state has good comprehensive mechanical properties. In addition to strength and plasticity, its hardness, wear resistance and other properties are also excellent. In some application scenarios that need to withstand friction and wear, the 7075 T4 aluminum alloy can rely on its good wear resistance to ensure the long-term stable operation of parts.

Ordinary corrosion resistance: The 7075 T4 aluminum alloy has ordinary corrosion resistance and can resist a certain degree of corrosion in general atmospheric environments and conventional industrial environments. However, compared with T351, its corrosion resistance may be slightly inferior, but its corrosion resistance can be further improved through appropriate surface treatment, such as anodizing.

Application fields

Automobile manufacturing: In the automotive industry, 7075 T4 aluminum alloy is often used to manufacture some key parts of automobiles, such as automobile wheels, engine parts, etc. Automobile wheels need to have a certain strength and good plasticity to ensure that they will not break when bearing the weight of the vehicle and various impact forces during driving. At the same time, good plasticity is conducive to the forging and forming of the wheel.

Engine parts, such as pistons and connecting rods, have high requirements for material strength, wear resistance and lightness. 7075 T4 aluminum alloy can reduce the weight of the engine and improve the fuel economy of the car while meeting the strength and wear resistance.

Sports goods manufacturing: In the field of sports goods, 7075 T4 aluminum alloy is also widely used. For example, golf club shafts, bicycle frames and other products are often made of 7075 T4 aluminum alloy. Golf club shafts require high strength and good elasticity, and 7075 T4 aluminum alloy meets these requirements, allowing the club to produce appropriate elastic deformation when hitting the ball, improving the impact. Bicycle frames, on the other hand, need to be as light as possible while maintaining strength. The performance characteristics of 7075 T4 aluminum alloy enable the manufacture of strong yet lightweight bicycle frames, improving riding comfort and speed.

Original Source:https://www.aircraftaluminium.com/a/7075-t351-vs-t4.html

Al 5754 H111 VS H22

La aleación de aluminio 5754, una aleación de Al-Mg con magnesio como principal elemento de aleación, se utiliza ampliamente en el sector industrial gracias a su excelente resistencia a la corrosión, resistencia media y buen rendimiento de procesamiento. La diversidad de su rendimiento se debe en gran medida a los diferentes tratamientos térmicos y estados de procesamiento, como O, H111, H22, H32, etc.

Los diferentes temples confieren a la hoja de aluminio 575 propiedades diferenciadas mediante el control del proceso. Entre ellos, H111 y H22 presentan características propias en cuanto al equilibrio entre resistencia y plasticidad, y se han convertido en los dos temples más frecuentemente comparados en aplicaciones de resistencia media y baja.

Diferencias de proceso

Proceso H111

El núcleo del estado al 5754 h111 es el "endurecimiento por acritud suave", que suele formarse de forma natural durante el proceso de conformado del material. Este proceso conserva la buena plasticidad original del material, con una tensión interna extremadamente baja, y es adecuado para procesos que requieren un conformado complejo posterior (como el doblado y el estampado).

Proceso H22

H22 es un proceso compuesto por endurecimiento por acritud y recocido parcial. El material final conserva una alta resistencia a la vez que recupera ligeramente su plasticidad, equilibrando la alta resistencia y la maquinabilidad.

Diferencias en las propiedades físicas

Densidad y punto de fusión

Ambos tienen una densidad de 2,66 g/cm³ y un rango de punto de fusión de 590-650 °C, determinado por la composición fija de la aleación 5754 (Al ≥95 %, Mg 2,6 %-3,6 %) y no se ve afectado por el estado de procesamiento.

Expansión térmica y conductividad térmica

Coeficiente de expansión térmica: H111 es de 23,4 × 10⁻⁶/℃ a 20-100 °C; H22 tiene un coeficiente de expansión térmica ligeramente superior (23,6 × 10⁻⁶/℃) debido a una distorsión reticular ligeramente mayor tras el procesamiento. Esta diferencia debe tenerse en cuenta en soldaduras de precisión o entornos de alta temperatura.

Conductividad térmica: El H111 tiene una conductividad térmica de aproximadamente 126 W/(m·K), mientras que el H22 tiene una conductividad térmica de 123 W/(m·K) debido a dislocaciones que dificultan la conducción del calor, lo que tiene un impacto más evidente en los componentes de disipación de calor, como los radiadores.

Diferencias en las propiedades mecánicas

Resistencia y plasticidad

Resistencia a la tracción: H111 es de 190-240 MPa, mientras que H22 aumenta a 220-270 MPa, lo que representa un aumento de aproximadamente el 15 %.

Límite elástico: H111 es de aproximadamente 80 MPa, mientras que H22 aumenta significativamente a 130 MPa debido al refuerzo por dislocación, lo que representa un aumento del 62,5 %.

Elongación: H111 mantiene una alta plasticidad del 12 % al 18 %, mientras que H22 pierde algo de plasticidad debido al endurecimiento por acritud, y la elongación disminuye al 7 % al 12 %.

Dureza y tenacidad

La dureza Brinell de H111 es de aproximadamente 38 HBW y presenta una buena tenacidad (energía de impacto ≥ 25 J). La dureza del H₂₂ aumenta a 63 HBW, pero la tenacidad disminuye ligeramente (energía de impacto 18-22 J), lo que refleja la ley típica de "aumento de la resistencia acompañado de sacrificio de la tenacidad".

Diferencias en las propiedades químicas

Resistencia a la corrosión

Ambas mantienen la excelente resistencia a la corrosión de la aleación 5754. La película de pasivación formada por magnesio es densa y estable, y la tasa de corrosión en agua de mar y atmósferas húmedas es inferior a 0,01 mm/año.

Sin embargo, el aluminium 5754 h22 puede producir defectos de contorno de grano durante el proceso de procesamiento. En un entorno de alta concentración de iones cloruro (como la prueba de niebla salina), su tasa de corrosión es aproximadamente un 5 %-8 % mayor que la del H₂₂. Si bien la diferencia es pequeña, debe tenerse en cuenta en entornos extremos.

Estabilidad química de la soldadura

Durante la soldadura, el H₂₂ no es propenso a la corrosión intergranular en la zona afectada por el calor (ZAC) debido a su baja tensión interna. El estado parcialmente recocido del H22 puede causar un reblandecimiento local de la ZAT. Si el proceso de soldadura no es el adecuado, la sensibilidad a la corrosión es ligeramente superior a la del H111, lo que debe mitigarse controlando la temperatura de soldadura (<450 °C).

Diferencias de aplicación

Escenarios típicos del H111

Ámbito automotriz: paneles interiores de puertas, soportes de paneles de instrumentos (se requiere estampado complejo);

Decoración arquitectónica: paneles de muro cortina de aleación de aluminio, techos (se requiere buen rendimiento de flexión);

Fabricación de contenedores: latas de envasado de alimentos, tanques de almacenamiento de líquidos (no se requiere agrietamiento por tensión después de la soldadura).

Áreas de ventaja del H22

Transporte: suelo de compartimentos de camiones, paneles laterales de barcos (se requiere resistencia al impacto);

Ingeniería estructural: soportes ligeros, vigas de estanterías (se requiere capacidad de carga);

Equipamiento para exteriores: estructuras de remolques de camping, carcasas de equipos portátiles (se requieren resistencia y ligereza).

Fuente original: https://www.placadealuminio.es/a/al-5754-h111-vs-h22.html

AA6016 6111 Aluminum Alloy

In the process of the automotive industry's continuous pursuit of lightweight and high performance, aluminum alloys have gradually become the key driving force for industry change with their excellent comprehensive performance. As outstanding representatives of the aluminum alloy family, 6016 and 6111 aluminum alloys are increasingly widely used in the automotive field, bringing new ideas and solutions to automotive design and manufacturing.

6111 and 6016 aluminum properties

6016 and 6111 aluminum alloys belong to the 6xxx series of aluminum alloys, with magnesium (Mg) and silicon (Si) as the main alloying elements. There are certain differences in composition and performance.

AA6016 aluminium has a low copper (Cu) content and has good fracture toughness, corrosion resistance and fatigue resistance. Its elongation can reach 22-25%, far exceeding the 15-20% of ordinary steel, which makes it perform well when stamping complex curved surfaces and can meet the complex shape requirements of automotive exterior panels.

6111 aluminum alloy has a relatively high copper content, and its strength and hardness are more outstanding. Its elongation is between 20-23%, which is also better than ordinary steel. After hardening by baking paint, its strength can be significantly improved, providing better dent resistance for automotive parts.

Application in the automotive field

In automobile manufacturing, 6016 and 6111 aluminum alloys are mainly used in automobile exterior covering parts, such as automobile hood outer panels, door panels and other parts. Taking the automobile hood outer panel as an example, as an important part of the car body, it must not only have good aerodynamic performance and aesthetics, but also take into account lightweight, safety and feasibility of manufacturing processes.

6016 and 6111 aluminum alloys can stamp out complex streamline shapes with their high elongation and low rebound rate, and the rebound angle after stamping is only about 3-5°, which effectively reduces dimensional deviation and ensures assembly accuracy.

At the same time, these two aluminum alloys have smooth surfaces, no orange peel after spraying, and good corrosion resistance. Relying on the protection of natural oxide film, they are not easy to rust after long-term use, and can maintain the beauty and integrity of the car's appearance.

In the application of car doors, 6016 aluminum alloy can meet the anti-dent design requirements of the door by increasing the thickness of the sheet and optimizing the structure. On the premise of meeting the rigidity, strength design requirements and relevant collision regulations, the use of 6016 aluminum alloy sheets can reduce the weight of the door by more than 40%, achieving a significant lightweight effect, and reducing the energy consumption and emissions of the whole vehicle.

Process maturity analysis

From the perspective of research and development history, developed countries with automobile industries such as Europe, the United States, and Japan have begun to develop automotive aluminum alloys since the 1970s. In the early 1980s, Alcan and Aluminum of Switzerland successfully developed high-Cu 6111 aluminum alloy and low-Cu 6016 aluminum alloy respectively.

After years of development and practice, the processing technology for 6016 and 6111 aluminum alloys has become relatively mature. The use of advanced rolling equipment and processes can accurately control the thickness, flatness and surface quality of the aluminum plate to meet the high-precision requirements of automotive parts.

In terms of heat treatment, Haomei Aluminum has determined the optimized process parameters such as 560℃/1min solution treatment + 80℃/6h pre-aging treatment, which can make the plate have good forming performance before stamping, and can quickly improve the strength during the baking process after stamping, so as to obtain ideal comprehensive performance.

In the surface treatment stage, the mature application of processes such as anodizing, coating treatment, and passivation treatment has further improved the corrosion resistance and aesthetics of aluminum alloy plates, meeting the automotive industry's strict requirements on product appearance and protective performance.

Original Source:https://www.autoaluminumsheet.com/a/aa6016-6111-aluminum-alloy.html

Aluminum Foil Winding in Transformer

Among the many components of a transformer, the winding is undoubtedly one of the key components, and its performance directly affects the overall performance of the transformer. Foil winding in transformer commonly chooses aluminum foil or copper coil.

Advantages of aluminum foil in foil winding

Cost and weight advantages

Aluminum is abundant in the earth's crust and is cheaper than copper. In transformer production, using aluminum foil as a winding material can significantly reduce the cost of raw materials. For example, if an aluminum foil winding is used for a transformer with a capacity of 1000kVA, the material cost can be reduced by about 20% - 30%. Moreover, the density of aluminum is only about one-third of that of copper, which greatly reduces the weight of transformers using aluminum foil winding.

For some application scenarios with strict weight requirements, such as mobile substations and transformers in the aviation field, the lightweight advantages of aluminum foil windings are particularly prominent, which is convenient for transportation and installation, and can reduce energy consumption during equipment operation.

Good electrical conductivity and heat dissipation performance

Although the electrical conductivity of aluminum is slightly lower than that of copper, the electrical conductivity requirements of the transformer can be met by rationally designing the cross-sectional area of the aluminum foil. At the same time, the aluminum foil has good thermal conductivity and can quickly dissipate the heat generated by the winding.

In actual operation, the transformer winding will generate heat due to the passage of current. If the heat cannot be dissipated in time, the winding temperature will rise, affecting the performance and life of the transformer. The heat dissipation advantage of aluminum foil winding can effectively suppress the generation of hot spot temperature of the winding. For example, in the high temperature environment in summer, the winding temperature of the transformer using aluminum foil winding can be 5-10℃ lower than that of the copper foil winding, which greatly improves the stability and reliability of the transformer operation.

Mechanical strength and short-circuit resistance

After proper processing, aluminum foil has good mechanical strength and is not easy to deform. During the operation of the transformer, especially when a short circuit occurs, the winding will be subjected to strong electromagnetic force. Aluminum foil winding can withstand large short-circuit forces and reduce the risk of winding deformation and damage due to their mechanical strength and structural characteristics.

Relevant experiments show that in simulated short-circuit tests, the winding integrity rate of aluminum foil winding transformers is 15% - 20% higher than that of ordinary winding transformers, effectively ensuring the safety of the transformer in the event of a fault.

Application cases of aluminum foil in foil winding

In developed countries such as Europe, America, and Japan, the application of aluminum foil for transformer is very common. Take Fuji Electric of Japan as an example. Its dry-type transformers widely use aluminum foil with high-tech physical properties containing rare earth metals as conductors for high and low voltage coils.

This kind of aluminum foil not only maintains good conductivity, but also improves mechanical strength, has a bright surface and is not easy to oxidize. The transformer using this aluminum foil winding has achieved miniaturization and lightness, and has excellent cracking and aging resistance, and the product service life has been increased to more than 40 years.

Challenges and Solutions of Aluminum Foil in Foil Winding

Although aluminum foil has many advantages in transformer foil windings, it also faces some challenges. Among them, the copper-aluminum connection problem is a more prominent one. To solve this problem, special welding processes and transition connection materials are often used.

In addition, the control of the oxide layer on the surface of the aluminum foil is also a key link. Although the natural oxide layer on the surface of the aluminum foil has a certain insulation effect, it may affect the electrical performance of the winding in some cases. By adopting surface treatment technologies such as anodizing, the thickness and quality of the oxide layer can be accurately controlled to better meet the insulation requirements of the winding.

Original Source: https://www.alumfoils.com/a/aluminum-foil-winding-in-transformer.html

How Is FSW Aluminium for Shipbuilding Produced #aluminum #shipbuilding

Haomei Aluminum provide wide and extra wide aluminum FSW plate for the superstructure of the ships. It will help you shorten the constructio...

-

The plate used in the CTF process is mainly PS plate , which is pre-coated photosensitive plate, which is developed to adapt to the rapi...

-

With the spread of energy saving and emission reduction concept, lightweight vehicles have been quickly promoted. Aluminum alloy is one of...

-

In the vast world of aluminum alloys, 5052 and 5754 aluminum alloys have become effective materials in many fields due to their unique pro...