With 20 years'development, Haomei has grown into a top aluminium alloy manufacturers and suppliers. We have comprehensive kinds of aluminium sheets, aluminum coil, aluminum strip, aluminum foil, aluminum discs, aluminum tread plate, color coated aluminum and CTP plates, covering series-1, series-3,series-5, series-6 and series-8. You can realize one-stop purchase in Haomei.

How Is White Aluminum Coil Produced

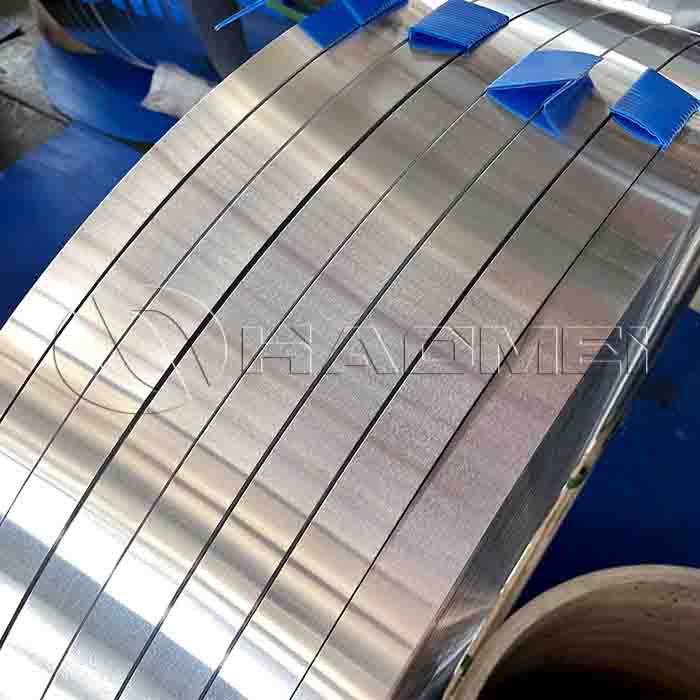

What Is The Aluminum Strip Width

Aluminum strips for sale are widely used in cables, transformers, electronic appliances, lamp manufacturing, blade manufacturing, radiators, hardware stamping parts, etc. Usually, the width of aluminum strips is cut according to the actual width required by users, which can reduce waste, reduce processing steps (no cutting), and save raw material costs.

The width of the aluminum strip is related to the slitting equipment. The aluminum strip adopts the longitudinal shearing of the aluminum coil, which is what we commonly call rolling shearing. The width of the aluminum strip can be controlled by the row of knives, and the width can be 3 mm.

Haomei Aluminum’s aluminum strip slitting equipment is all from Germany, which can effectively control the width tolerance and control the tolerance within 0.05mm. At present, it can slit aluminum strips with a thickness of 0.15-3.0mm like 2mm aluminium strip.

Generally, during the production and slitting process, the tolerance of the aluminum strip is within the lower tolerance, generally within -0.1mm, mainly considering the problem of continuous stamping dies. If the tolerance is positive, the die will get stuck with the aluminum strip during the continuous stamping process. Of course, if this problem occurs, the width of the die can be appropriately modified.

According to user requirements, various inner and outer diameter aluminum strip products are processed, and sleeves are used inside to avoid deformation of the aluminum strip, which is more convenient for subsequent processing. If there are special requirements for customized aluminum strips, they must be stated in the contract, such as outer diameter, inner diameter, whether the surface is filmed, and specific requirements for packaging.

The thickness and width standards of transformer aluminum strips are formulated to ensure the normal operation and safe use of transformers. When selecting transformer aluminum strips, we should choose the thickness and width that meet the standards according to actual needs. The width standards of transformer aluminum strips are generally 30mm, 80mm and 50mm aluminium strips.

Now aluminum strips have become the preferred product for many lighting companies. Using this product can reduce the amount of waste produced. If the lighting manufacturers purchase aluminum plates, they have to cut them and pay attention to scratches and other problems during the cutting process. If aluminum strip are used, the cutting will be removed and processign cost will be saved.

Original source: https://www.aluminumstrip24.com/news/what-is-the-aluminum-strip-width.html

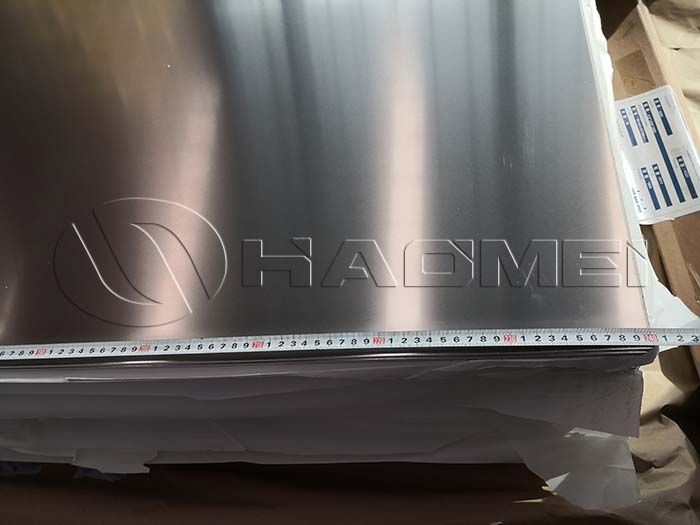

2024 T4 and 7075 T6 Aluminum Alloy

Al-Cu-Mg alloys are one of the most important alloy families of heat-treatable aluminum alloys. The most widely used alloy of this type in aircraft structures is 2024 aluminum alloy. The hardness of 2024t3 aluminum alloy is about HB120, and 2024t4 aluminum alloy reaches about HB140.

2024 aluminum alloy is an aluminum alloy with copper as the main alloying element. It is used in applications that require a high strength-to-weight ratio and good fatigue resistance. It can only be welded by friction welding and has moderate machinability. Due to its poor corrosion resistance, it is usually protected with aluminum or Al-1Zn cladding, although this may reduce fatigue strength.

2024 aluminum alloy is mainly used in aircraft structures with high strength requirements, such as fuselage, wings, belly plates, etc. In addition to high toughness, 2014 aluminum alloy also has many advantages such as stress corrosion resistance and fatigue resistance, so it is often used in the manufacture of civil aircraft such as Boeing and Airbus. 2224 aluminum alloy is a product obtained by further optimization of 2024 aluminum alloy.

7075 alloy is a heat-treatable and strengthened high-strength deformable aluminum alloy of aluminum-zinc-magnesium-copper system. It is the elder of super-hard aluminum. The common tempers are 7075 t6 aluminum and 7075 t73 aluminum.

It is used to manufacture various structural parts, especially aerospace structural parts. It is the most widely used high-strength aluminum alloy today.

In the state of solid solution treatment and artificial aging T6, the plasticity of 7075 alloy is slightly lower than 2024T6 and slightly higher than 7A04T6. The plate is notch-sensitive to static fatigue and has better stress corrosion performance than 7A04.

In order to enhance its corrosion resistance, it needs to be over-aged. The common treatment is T73, that is, the aluminum alloy is firstly solid solution treated, and then double-stage aging treatment is performed (after heating and keeping warm at a lower temperature for a period of time, then heating and keeping warm at a higher temperature for a period of time).

After this treatment, although the tensile strength of the material decreases by about 15%, the material's stress corrosion resistance and intergranular corrosion resistance are greatly improved. Haomei Aluminum has both 7075 and 2024 aluminum sheet. Welcome to leave message below to inquire what you need.

Original source: https://www.aircraft-aluminium-sheet.com/a/2024-t4-and-7075-t6-aluminum-alloy.html

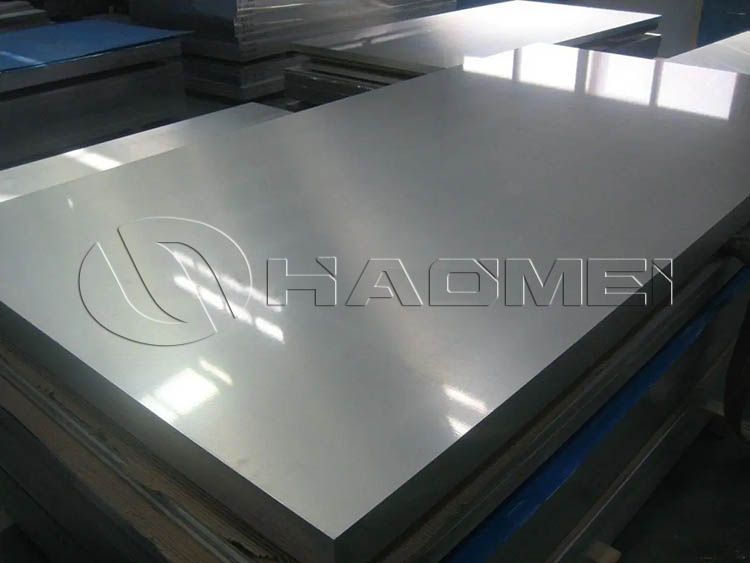

6016 5754 Aluminum for Car Door Panel

Automotive aluminum sheets are widely used in the automobile manufacturing industry. They ae well known for light weight, high strength, corrosion resistance and good forming performance. The use of automobile aluminum sheet can effectively reduce the overall weight of the car, improve fuel economy, and provide better safety performance and driving experience.

At present, the most widely used automotive aluminum sheets in the world are: AA6016, AA6022, AA6111, AA6005, AA6009 and AA6010, AA5182, AA5754, AA5052, etc. For example: Audi A8 uses 6016 alloy as car body sheet, Jaguar XJ220 and GM EV1 use 5754 aluminum plate as body cover material.

Based on the superior performance of 5754 aluminum sheet itself, it is favored by automobile manufacturers and is widely used in the production of automobile door inner panels, structural parts, and trunk covers. It has the advantages of high strength, good plasticity, high specific strength, good welding performance, strong temperature resistance, good corrosion resistance, and high fatigue strength.

6016 aluminum alloy is one of the main products of 6 series alloys and an important alloy for 6 series alloys to enter the automotive field. 6016 plates can already meet the highest requirements of some automobile manufacturers for outer panels of covering parts.

6016 t4 aluminum is mainly used for the car outer door. It has lower strength and better formability before stamping. Baking after stamping further increases the yield strength, thereby increasing the dent resistance of the cover made of it.

Although its strength cannot be compared with 2XXX series or 7XXX series, its magnesium and silicon alloys have many properties, including processability, excellent characteristics and electroplating properties, good corrosion resistance, high toughness and no deformation after processing.

One of the main factors affecting the wide-scale application of aluminum alloy automotive sheets is cost and price; however, with the increase in aluminum alloy sheet production and the decline in sheet manufacturing costs, the cost of aluminum alloy sheet stampings will drop significantly, while aluminum alloy lightweighting effect will be more significan. Haomei Aluminum has been devoted to providing 5xxx and 6xxx automotive aluminum sheets.

Original source: https://www.aluminium-auto-sheet.com/a/6016-5754-aluminum-for-car-door-panel.html

Mareine Aluminum 5000 and 6000 Series

Aluminum alloys basically have 8 series, among which only 5000 and 6000 series marine grade aluminum alloys are internationally recognized and can be used on ships. Haomei Aluminum, one of the big marine aluminum suppliers in China, likes to have a highlight of the popular marine aluminum alloys.

5083 aluminum plate is an aluminum alloy plate specially used for shipbuilding with medium and thick aluminum plates being the most commonly used. It is widely used for its good corrosion resistance, welding performance and mechanical properties. Its common tempers are H111, H112, H116, and H321, among which 5083-h116 aluminum plates are most widely used on ships.

In the shipbuilding industry, 5083 aluminum plates are widely used in hull structures, outfitting parts, decks, cabin bulkheads and other parts. Its excellent corrosion resistance and welding performance make ships have a long service life and low maintenance costs in seawater environments.

5059 aluminum alloy is the most advanced marine aluminum alloy. 5059 is an aluminum alloy with high strength, excellent corrosion resistance and heat resistance. It has high strength, especially after heat treatment, it can obtain higher strength and hardness. Its application is not as extensive as 5083.

6061 aluminum is a widely used 6000 series aluminum alloy. It realizes an excellent balance between strength, corrosion resistance, and machinability. The main alloying elements in 6061 aluminum are magnesium and silicon, which form magnesium silicide, improving its mechanical properties. The alloy also has good weldability, making it suitable for projects that require machining and welding.

6082 is a heat-treated alloy that can maintain good operability after annealing. It is mainly used in mechanical structures, including bars, plates, pipes and profiles. It is a commonly used aluminum alloy material for domestic and foreign shipbuilding companies.

Heat treatment is an important part of the 6 series aluminum alloy processing process. It improves its mechanical properties by changing the microstructure of the material. The typical heat treatment process of 6 series aluminum alloy is T6 state treatment. 6082T6 state has higher mechanical properties. Welcome to learn more about al 6082 t6 properties.

Original source: https://www.marine-aluminium-plate.com/a/mareine-aluminum-5000-and-6000-series.html

Aluminium 5083 h111 and Al 5754 h22 Properties

5083 aluminum plate belongs to Al-Mg alloy with the main alloying element Mg and a small amount of other elements such as silicon (Si). For example, the maximum content of silicon is usually no more than 0.40%. Its common tempers are H111, H112, H116, H321, etc.

Aluminium 5083 h111 is suitable for products that have undergone a moderate amount of work hardening after final annealing, but the degree of work hardening is not as good as that of the H11 temper. The 5083H112 temper is suitable for the free processing state of hot-rolled plates and hot-processed products.

5083-O and 5083-h111 aluminum sheethas a sufficient market practice basis as a powder tanker tank material in European powder tankers. Compared with steel trailers, aluminum alloy trailers can effectively achieve overall lightweighting of the vehicle, improve load-bearing performance, and improve transportation efficiency.

The common width of 5083 ultra-wide aluminum plates purchased by tank truck companies is 2.2 meters, and the thickness is 5mm, 6mm, 7mm, 8mm. A tank truck is usually made of 4-6 ultra-wide aluminum plates. In recent years, government departments have increased their advocacy for all-aluminum tank trucks and environmental requirements for energy conservation and emission reduction, and the demand for 5083 ultra-wide aluminum plates is further increasing.

5754 aluminum alloy is a kind of material for making tank cars. It is a typical alloy in the Al-Mg alloy system and contains 2.6-3.6% magnesium. The commonly used tempes are Al 5754 h22,H12, H14, H114, etc. 5754 medium and thick plates have the characteristics of medium strength, good corrosion resistance, weldability and easy processing and forming.

At 320℃ ~ 340℃, the 5754 aluminum undergoes partial recrystallization, the strength decreases rapidly, and the elongation increases; after annealing at 330℃ for 3min, the material's tensile strength, yield strength, and elongation are 250MPa, 150MPa, and 15.4%, respectively. This process can be used to guide the production of 5754-H22 state products on the continuous annealing line.

Haomei Aluminum can produce 5083 and 5754 aluminum sheets in different tempers with a thickness range of 0.15-600mm, a width range of 20-2650mm, and a length range of 500-16000mm, to meet the diverse needs of different customers. Welcome to leave message below to inquire what you need.

Original source: https://www.aluminium-tanker-plate.com/a/aluminium-5083-h111-and-al-5754-h22-properties.html

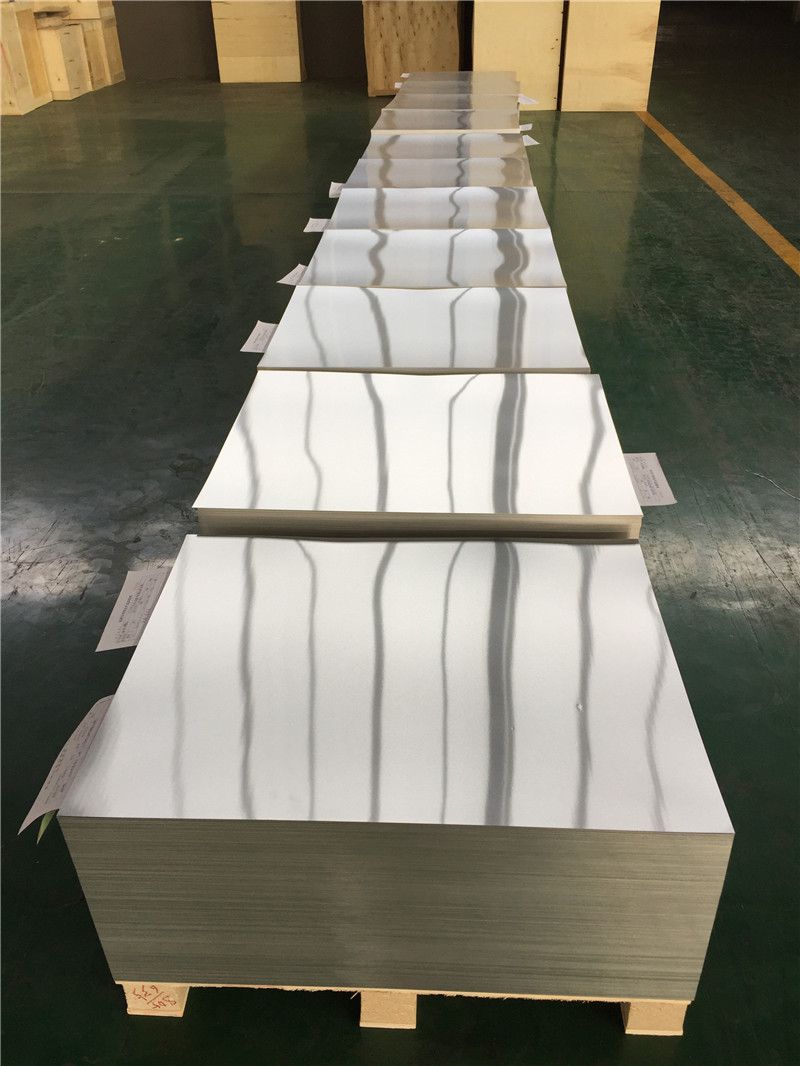

EN AW Aluminum 5083 5754 for Special Vehicles

EN AW-5754 aluminium sheet belongs to the Almg3 series, with a magnesium alloy content of 2.6-3.6, and is an aluminum alloy sheet with high hardness. Usually, 5754 aluminum sheet will be annealed to H111 or HO temper, because it can only be bent in this temper.

Since the price of 5754 aluminum plate is much higher than that of ordinary aluminum alloy plate, 5754 aluminum plate is usually used in places that require high corrosion and high strength, such as chemical tanks, high-pressure containers, etc.

The corrosion resistance of 5754 aluminum plate is tested through microscopic inspection of metals and alloys. It has excellent stress corrosion resistance and exfoliation corrosion resistance. It can be used for a long time in various media (such as water vapor, weak alkali, etc.) without pits or blackening.

5754 aluminum alloy is also suitable for collision energy absorption parts in automobile manufacturing, such as anti-collision beams, door frames, etc. At the same time, with its high corrosion resistance, 5754 aluminum tubes are also suitable for building curtain wall systems, rail transit vehicle structures, aerospace components, and food processing equipment.

The main characteristics of 5083 aluminum alloy are low density, high tensile strength and high elongation. In addition, it has extremely high resistance to seawater and chemical environment as well as stress corrosion cracking. Therefore, it is often used in rail transportation, automobiles, aerospace and ships.

5083 aluminum has good welding performance and can be processed by various welding methods, such as manual arc welding, TIG welding, MIG welding, etc. In addition, 5083 aluminum plate also has excellent fatigue resistance and is suitable for structural parts that withstand repeated loading and unloading.

At present, most tank truck manufacturers mainly use 5083 aluminum alloy plate as the raw material. 5083 (O/H111) aluminum sheet has a sufficient market practice basis as a powder tanker tank material on European powder tankers. 5083 aluminum tankers can be used to load oil, gasoline, chemicals, cement and other dense materials.

AW 5083 aluminium is also mainly used in gas storage devices in automobile brake systems. Its main alloying element is magnesium, which has the advantages of good corrosion resistance, light weight, good cold workability, and medium strength. Compared with traditional iron gas cylinders, aluminum alloy gas cylinders are lighter, more durable, and safer. Welcome to inquire aluminium 5083 price from us.

Original Source:https://www.aluminumtankerplate.com/a/en-aw-aluminum-5083-5754-for-special-vehicles.html

5xxx Aluminum Sheets

5083 aluminum tread plate

5083 aluminum plate is of excellent anti-slip and anti-rust function. It has good plasticity, excellent forming properties and strong weldability. Gas welding, arc welding, contact spot welding and wire welding can be used.

In the production process of 5083 diamond tread plate, we add added a small amount of Be to reduce the tendency of ingot cracking and improve the surface quality of the rolled plate.

5754 aluminum checker plate

It is with medium to high strength. Because of its good corrosion resistance, it is called rust-proof aluminum plate. We has a strict control of Mg content to ensure low cracking tendency during welding.

5086 aluminum 5 bar tread plate

It has high corrosion resistance, good weldability and medium strength, which is often used in ships and automobiles. It has many tempers such as O, H12, H14, H16, H18, H19, H22,etc. The thickness is 0.15-600 mm. The width is 20-2650 mm. And the length is 500-16000 mm.

5052 aluminum diamond plate

It has good corrosion resistance, hardness and rust resistance. Its price is also relatively cheaper than other 5xxx series aluminum plate. The width of 5052 aluminum plate can reach 2800mm. Its common tempers are O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32,etc.

As a big aluminum tread plate supplier, Haomei Aluminum 5 bar tread plate covers 1,3,5 and 6 series. Welcome to leave message below to get the best price.

Original source: https://www.hm-alu.com/a/5xxx-aluminum-sheets.html

What Are Duralumin Uses

The duralumin alloys are usually 7xxx, 2xxx and 6xxx aluminum alloys. 7075aluminum plate is one of the most commonly used aluminum alloys with the highest strength. The anodizing 7075 aluminum has higher strength.

In the aviation field, it is mainly used to make aircraft skins, fuselage frames, beams, propellers, fuel tanks, wall panels and landing gear struts, as well as streamlined covers, turntables, remote controls and main components of space launch vehicles, and engine devices. It is also widely used in the fastener industry, mainly for the production of various nuts and shear-resistant high-lock nuts.

7050 is a high-strength alloy of Al-Zn-Mg-Cu series, which can be strengthened by heat treatment. The chemical composition of this aluminum alloy is adjusted on the basis of 7075 super-hard aluminum alloy, the content of zinc and copper is increased, zirconium is used instead of chromium to refine the grains, and the content of impurities such as silicon and iron is reduced.

7050 aluminum is mainly used for main load-bearing structural parts with high strength, good fracture toughness, and high resistance to stress corrosion cracking and exfoliation corrosion, such as thick plates, extrusions, free forgings and die forgings for aircraft structures, such as thick plates, extrusions, free forgings and die forgings for aircraft structures, including fuselage frames, partitions, wing beams, landing gear support parts and rivets.

6063 aluminum is widely used in the development of aircraft-related structures, such as fuselages and wings. 6063 aluminum alloy is available in a variety of forms to meet the needs of different applications.

Whether the application involves bicycle parts, military-grade rifles or plastic industrial molds, 6063 alloy is usually selected. Other types of high-stress structural parts, such as gears, fuse parts and bows, are also made of 6063 aluminum alloy.

2024 aluminum alloy has excellent mechanical properties and corrosion resistance, and is widely used in aerospace, automobile manufacturing, shipbuilding and other fields. 2024 has relatively good fatigue resistance, especially in thick plates, making it suitable for most aircraft structures. 2024 t3 and t4 are its main tempers. Welcome to inquire 2024 t3 aluminum sheet price from us.

2014 aluminum is used to manufacture rims that require high strength, high hardness and withstand high loads, such as rims, truck frames and suspension assemblies, rocket booster fuel tanks and structural parts; 2014 coated aluminum can also be produced to improve its corrosion resistance.

Original Source:https://www.aircraftaluminium.com/a/what-are-duralumin-uses.html

Papel aluminio grueso para cocina

El papel de aluminio grueso para cocina es una de las herramientas de cocina más prácticas en la cocina. No solo puede acumular calor, sino que también permite que los alimentos absorban el calor más rápidamente, acortando en gran medida el tiempo necesario para cocinar. Al mismo tiempo, también puede mantener la comida caliente, por lo que en la vida real es una ayuda muy útil.

El papel de aluminio para cocinar se utiliza generalmente para cocinar al vapor y hornear alimentos en el horno. En términos generales, el grosor del papel de aluminio utilizado en los hornos domésticos debe ser inferior a 0,025 mm, es decir, menos de 25 micrones. El grosor del papel de aluminio para alimentos normal en el mercado es de aproximadamente 10 micrones a 20 micrones.

En la barbacoa, a menudo envolvemos la bandeja para hornear o toda la comida con este tipo de papel de aluminio. El primero es para limpiar, de modo que los utensilios de cocina no se contaminen con grasa u otras sustancias en la comida. El segundo es para calentar la comida de manera más uniforme y reducir la situación en la que algunas partes se queman y otras no se calientan por completo.

En el frigorífico o el congelador, se puede envolver la comida directamente con papel de aluminio para evitar que se deforme, evitar la pérdida de agua en el pescado, las verduras, las frutas y los platos, y evitar que se filtren o mezclen los sabores. Dado que el papel de aluminio tiene una conductividad térmica y un efecto de calentamiento buenos y uniformes, se puede utilizar en hornos, vaporeras, etc. para calentar directamente sobre el envase original.

Cuando utilice papel de aluminio, envuelva los alimentos con una superficie brillante. La superficie mate orientada hacia la fuente de calor puede acelerar la cocción. Sin embargo, la reflectividad de la superficie mate es del 80%, mientras que la superficie brillante es del 88%. Solo hay una pequeña diferencia entre los dos. En la vida diaria, no hay mucha diferencia.

El papel de aluminio de Haomei cumple con las regulaciones de la Administración de Alimentos y Medicamentos de los Estados Unidos (FDA) para materiales de envasado de alimentos. El contenido total de plomo, cadmio, mercurio y cromo hexavalente en los rollos grandes de papel de aluminio de Haomei a la venta cumple con las regulaciones de la Directiva 94/62/EC del Consejo Europeo. Bienvenido a dejar un mensaje a continuación para preguntar sobre el precio del papel aluminio 400 metros.

Original source: https://www.placadealuminio.es/a/papel-aluminio-grueso-para-cocina.html

What Are The Uses of 5083 and 5454 Aluminum Sheet in Automobile

As an Al-Mg alloy, 5454 aluminum sheet is a typical rust-proof aluminum with about the same strength as 5154 and about 20% greater than 5052. It is mostly used in automobile wheels. 5454 can adapt to harsh corrosive environments and is a typical rust-proof aluminum with high strength, about 20% higher than 5052 aluminum plate. 5454 aluminum plate is widely used in automobiles, aluminum tank truck body and other fields.

5083 Aluminum is alloyed with magnesium and trace amounts of manganese and chromium. 5083 alloy retains very high strength after welding. It is the strongest of the non-heat-treatable alloys, but is not recommended for use above 65°C.

5083 aluminum alloy has a variety of applications in automobile manufacturing, mainly due to its characteristics such as lightweight, corrosion resistance and machinability. Here are some common applications of 5083 aluminum alloy in automobile manufacturing:

Body structure: 5083 aluminum alloy can be used in the manufacture of automotive body structures, such as body frames, doors, trunk lids and hoods. Due to the lightweight characteristics of 5083 alloy, it can reduce the weight of the vehicle body, improve fuel efficiency and performance, while maintaining sufficient strength.

Wheels: 5083 aluminum alloy is also used to make hubs and spokes because its corrosion resistance and strength enable it to withstand the challenges of road conditions and meteorological environments.

Suspension components: 5083 aluminum alloy can be used to manufacture suspension components such as suspension arms, suspension brackets, and shock absorbers. Lightweight suspension components can improve the suspension performance and handling of the vehicle.

Fuel tanks and exhaust systems: 5083 aluminum alloy can also be used to manufacture components of fuel tanks and exhaust systems. Due to its corrosion resistance, it can reduce corrosion and oil leakage problems in these parts.

Interior parts: 5083 aluminum alloy can also be used in automotive interior parts such as dashboards, door panels and seat structures. It can provide a beautiful appearance and withstand daily wear and tear.

Chassis components: 5083 aluminum alloy can be used to manufacture chassis components such as trays, suspension elements and chassis brackets, providing sufficient strength while reducing the weight of the chassis.

In general, the application of OEM 5083 aluminum plate in automobile manufacturing helps to reduce vehicle weight, improve fuel efficiency and reduce exhaust emissions, so it is very popular in the modern automotive industry. However, choosing the right aluminum alloy and appropriate process are essential to ensure the performance and safety of the car.

Original Source:https://www.autoaluminumsheet.com/a/what-are-the-uses-of-5083-and-5454-aluminum-sheet-in-automobile.html

PTP Aluminum Foil for Blister Packaging

Compared with bottled tablets, the biggest advantage of blister packaging is that it is easy to carry and can reduce the pollution during the carrying and taking of medicines. The materials used for aluminum blister packaging are mainly PTP pharmaceutical aluminum foil and plastic hard sheets, which are mostly used to package tablets, pills and capsules.

The core value of PTP aluminum foil lies in its moisture and oxygen resistance. Thanks to the compact structure and excellent barrier properties of aluminum itself, PTP aluminum foil can ensure that drugs are not damp or oxidized during storage and transportation, maintain stable efficacy, and extend the shelf life of drugs.

This feature is particularly important for drugs that are sensitive to moisture and oxygen, such as biologics, easily degradable drugs, or tablets and capsules containing water-soluble ingredients. It is a key barrier to ensure that patients use medicines safely and have good efficacy.

On the technical level, the production of PTP aluminum foil integrates precision coating, composite processing and molding technology, and each link needs to be strictly controlled to ensure the high quality of the product. PTP medicinal aluminum foil alloy is usually 8011-H18 or 8011-O temper. The thickness is of 0.016-0.04mm.

PTP aluminum foil testing is a method for quality inspection of pharmaceutical packaging materials. PTP aluminum foil is a material commonly used in pharmaceutical packaging, with advantages such as moisture retention, gas and light barrier. It is mainly composed of aluminum foil and glue layer, which can effectively protect the quality and safety of drugs.

The pinhole requirement for aluminum foil used for medicine and health food is that the number of pinholes with a diameter of 0.1-0.3mm should not exceed 1/m2. Since pinholes in aluminum foil are penetrating defects, the health food and medicine will be reduced in efficacy or deteriorate when oxygen, water vapor and light penetrate into them, so the pinhole requirement is very strict. Welcome to inquire alu blister foil specification from us.

Original source: https://www.alumfoils.com/a/ptp-aluminum-foil-for-blister-packaging.html

What Is Used To Make Aluminum Ropp Cap

Ropp cap is a threadless aluminum cap used to seal glass bottles. ROPP caps are in great demand in the beverage and food industries and are widely used in alcoholic beverages, medical, pharmaceutical, beverages, food, edible oil, etc.

Carbonated soft drinks, energy drinks and alcoholic beverages are the main end-user areas of aluminum bottle caps and closures. In addition, the use of aluminum bottle caps in the wine industry is becoming more and more popular, as aluminum screw caps can better isolate oxygen from wine and are cost-effective compared to corks.

Aluminum cap for bottle is mostly processed on production lines with a high degree of automation, so the strength, elongation, dimensional deviation and other requirements of the bottle cap material are very strict, otherwise there will be fractures or creases during processing. The common alloys are 8011 aluminum foil.

The main elements of 8011 aluminum foil are Al-Fe-Si, and the rest are trace impurity elements. Its performance is better than pure aluminum foil. 8011 aluminum plate is not commonly used, but 8011 aluminum foil is widely used, especially in the field of bottle cap materials. 8011 aluminum foil is the main material for PP/ROPP bottle caps.

The composition and organization of the alloy determine the performance of the alloy. According to the role and mutual influence of the main alloying elements of the 8011 alloy, the main alloying element Fe content of the 8011 alloy is selected to be controlled at about the middle and upper limit of the alloy standard range (0.8%) to reduce the earing rate of th ealuminum alloy plate and improve the strength of the alloy.

At the same time, the Si content is controlled at about 0.75%, and the Fe/Si ratio of the alloy is reasonably selected (approximately equal to 1), which lays a good foundation for the subsequent correction of the alloy to obtain an ideal texture morphology.

8011 aluminum foil sheet can have different surface treatment like DOS oil coating, painting or color printing. All the used coating is of food grade. Food-grade environmentally friendly paint has good durability and adhesion to the coated objects after use, and can effectively protect the surface of the coated objects, prevent damage caused by moisture, stains, etc., and increase their service life.

Original Source: https://www.alclosuresheet.com/a/what-is-used-to-make-aluminum-ropp-cap.html

How to Choose Aluminum Profile for Different Applications

As an important building and industrial material, aluminum profiles are widely used in various fields. The selection of aluminum profiles of different alloys will affect the performance and applicable scenarios.

Al-Mg-Si alloy profile

It is an aluminum profile with high strength and rigidity. It adds magnesium and silicon elements to aluminum alloy profiles. It has better wear resistance and corrosion resistance and can cope with harsh environments and high pressure conditions.

Main applications

Automobile manufacturing: automobile body, chassis, frame, engine parts, etc.

Aerospace: aircraft structure, wings, spacecraft, etc.

Sports equipment: bicycles, mountaineering equipment, skiing equipment, etc.

6061 aluminum alloy

6061 alloy is often used to make aluminum boat extrusions like 6061 aluminum tubing. Its hardness and strength are higher than 6063 aluminum profile. It is suitable for scenes with large loads and stresses, such as building structures, mechanical equipment, etc. Its advantage lies in good corrosion resistance.

Main applications

Architecture: building structures, support columns, beams, etc.

Mechanical engineering: mechanical equipment, parts, molds, etc.

Aerospace: aircraft structures, parts, spacecraft, etc.

Automobile manufacturing: automobile chassis, frames, engine parts, etc.

6063 aluminum alloy

It has good machinability and corrosion resistance, and is suitable for scenes that require high-precision machining and surface treatment, such as doors and windows, curtain walls, industrial assembly line frames, radiators, etc. Its advantages are good plasticity, suitable for extrusion production, and a wide range of applications.

Main applications

Construction field: doors and windows, curtain walls, display racks, balcony railings, etc.

Interior decoration field: furniture, decorations, cabinets, floor strips, etc.

Industrial equipment: assembly line frames, robot fences, equipment racks, etc.

6082 aluminum alloy

Because it contains Mn, the corrosion resistance and welding performance of 6082 allooy are even better. Especially in marine ships, 6082 is widely used, and ship hull and components are inseparable from it.

6082 marine aluminium extrusions not only has excellent formability, weldability, machinability and corrosion resistance, but also has medium strength. Whether it is a bar, plate, pipe or profile, it can show excellent operability. In Europe and the United States, 6082 alloy is very popular and is widely used in various fields, such as seamless aluminum tubes and structural profiles.

Aluminum-titanium alloy profile

It is a high-strength, corrosion-resistant aluminum profile. Aluminum-titanium alloy profile is suitable for manufacturing lightweight structural parts and parts that bear high loads.

Main applications

Aerospace field: aircraft structure, engine parts, spacecraft, etc.

Transportation field: high-speed trains, subway vehicles, etc.

Original Source:https://www.marinealu.com/a/how-to-choose-aluminum-profile-for-different-applications.html

5251 5454 5083 Aluminum Sheet

5251 aluminum sheet was registered by the European Aluminum Association in 1972. It is a high-strength, corrosion-resistant and rust-proof aluminum. 5251 has good corrosion resistance, high strength, wear resistance and good welding performance. It is widely used for structural parts and pressure vessels in aerospace, automobiles, railways, ships, construction, metallurgy and other fields.

5251 aluminum alloy can be heat treated in various states, with high mechanical properties and hardness. The commn tempers are O, H32, H34, H36, etc., which can improve its strength and hardness. After heat treatment in H32 state, the hardness of 5251 aluminum alloy can reach 65~75HB.

Mechanical properties

Tensile strength: ≥215MPa

Yield strength: ≥95MPa

Elongation: ≥10%

Physical properties:

Density: 2.69 g/cm³

Coefficient of thermal expansion: 23.2 x 10^~6/℃

Thermal conductivity: 121 W/(m·K)

5454 aluminum sheet is an Al-Mg alloy with good anti-rust effect. It has high strength, about 20% higher than 5052 aluminum plate, which can adapt to relatively harsh environments, and has excellent corrosion resistance. In addition, 5454 aluminum plate also has good plasticity and good formability, and is mostly used in welding structures, pressure vessels, ships and marine facility pipelines, and tanker barrels.

The construction of marine pipelines requires materials to cope with the harsh marine environment, so choosing the right materials is critical. In this field, 5454 aluminum plate has attracted much attention due to its excellent performance and has become the preferred material for marine pipeline construction.

5083 plate is a non-heat-treatable alloy known for its resistance to extreme environments, including seawater corrosion and industrial chemicals. Due to its ultra-high strength with limited machinability, aluminium plate 5083 is the material of choice for marine and waterborne applications, often in shipbuilding. Other uses for this alloy include transportation applications such as rail, truck and car bodies, as well as pressure vessels and food processors.

5083-H116 aluminum plate is a hot-rolled aluminum plate. The main features of 5083-H116 aluminum plate are low density, high tensile strength, high elongation, good machinability, corrosion resistance and welding performance. As cars, ships and airplanes become important modern means of transportation, the demand for 5083-H116 aluminum plate will also increase.

Original Source: https://www.alumhm.com/a/5251-5454-5083-aluminum-sheet.html

Color Aluminum Strip for Ceiling

In interior decoration, suspended ceilings not only impact the overall visual effect but also their practicality and durability. Nowadays,...

-

The plate used in the CTF process is mainly PS plate , which is pre-coated photosensitive plate, which is developed to adapt to the rapi...

-

With the spread of energy saving and emission reduction concept, lightweight vehicles have been quickly promoted. Aluminum alloy is one of...

-

In the vast world of aluminum alloys, 5052 and 5754 aluminum alloys have become effective materials in many fields due to their unique pro...