Compared with ordinary aluminum alloys, aircraft aluminum for sale has higher requirements for strength, hardness, toughness, fatigue resistance and plasticity. Due to its light weight, aerospace aluminum has replaced steel and occupies the current leading position in aerospace materials.

The aluminum alloys used in the structure of aviation aircraft in the world today are mainly high-strength 2 series (2024, 2017, 2A12, etc.) and ultra-high-strength 7 series (7075, 7475, 7050, 7A04, etc.), and some 5 series (5A06, 5052, 5086, etc.) and 6 series (6061, 6082, etc.) and a small amount of other series aluminum.

6061 aluminum plate is the earliest 6XXX series aluminum alloy used in aviation. It has good corrosion resistance and excellent welding performance, but the strength is moderately low. It is more corrosion resistant, easier to weld, and more suitable for machining.

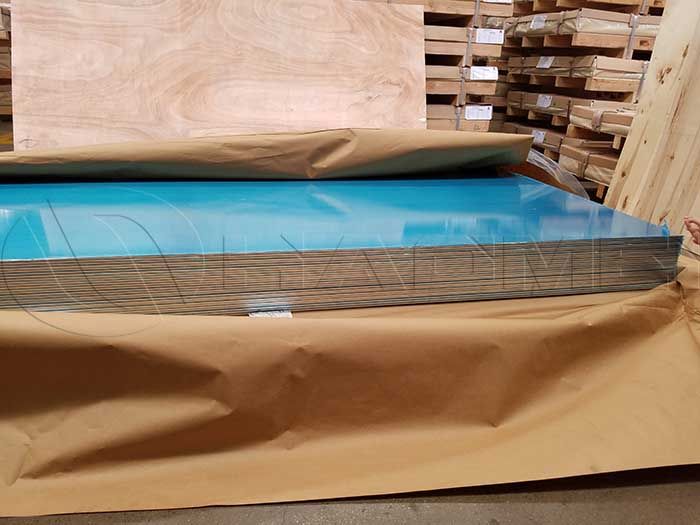

6061 aluminum sheet is made of high-quality aluminum alloy products through a special pre-stretching process, so that the 6061 alloy has good processing performance, good corrosion resistance, high toughness, good anodizing effect, and is not easy to deform after processing.

The main alloying elements of 6016 aluminum alloy are magnesium and silicon. The addition of magnesium increases strength, while the addition of silicon reduces the melting temperature of the metal. Typically, 6061 aluminum is solution heat treated and then aged. 6061 t6 aluminum for sale is artificially aged for higher strength.

6061 aluminum plate and 2A12 are both heat-treatable aluminum alloys. After heat treatment, the two are indistinguishable in appearance. Due to the huge price difference between the two, some aluminum alloy suppliers choose to use 6061 aluminum sheet to replace 2A12. How to tell their differences?

The hardness of the 6061 aluminum plate after heat treatment is 90HB, while the 2A12 can reach around 120HB. Hardness can be measured if you have a hardness measuring device. If you don't have a hardness tester, then there is a simple solution.

The density of the two is quite different. The density of 6061 can only reach 2.7, while the density of 2A12 can reach around 2.78-2.79 due to the high content of copper alloy. The density of the product can be calculated according to the formula for calculating the weight of the aluminum plate. Weight formula: thickness (mm) * density (2.7/2.78) * length (m) * width (m) = weight.

Original source: https://www.aircraft-aluminium-sheet.com/a/6061-aircraft-aluminum-for-sale.html