High strength aluminum alloys have he advantages of low density, high strength, and good thermal processing performance. Different forms of aluminum alloys like aluminum sheet have broad application prospects in aerospace components. For example, high-strength aluminum alloy thick plates are used as the main load-bearing components, and the proportion of use accounts for 30% to 35% of the total aluminum consumption in the aircraft.

Aluminum grade 7075 has zinc as the main alloying element, and as a member of the 7000 series, its strength is very high, comparable to many types of steel. Although it has high strength, it has lower corrosion resistance than other common aluminum alloys and does not provide the same level of machinability or weldability.

7075 aluminum plate was successfully developed in 1943. It is the first practical application of 7xxx aluminum alloy for the manufacture of various structural parts, especially aerospace structural parts. It is the most widely used high-strength aluminum alloy today.

It is widely used to make aircraft front fuselage truss, passenger observation window frame forgings, middle fuselage sheet bending and truss, keel beam web, floor turning beam, middle and rear fuselage truss, phone shell,etc. Its common tempers are T6, T73, T76 and T77.

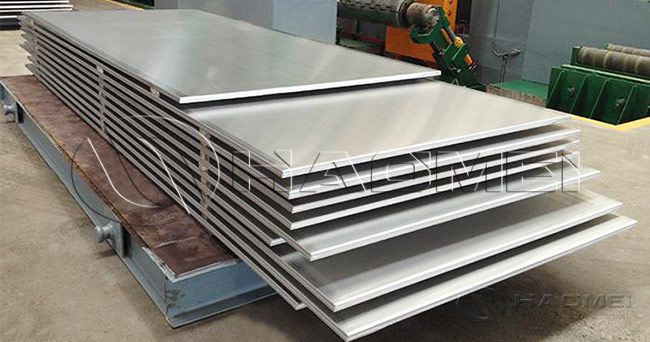

Haomei 7075 aluminum sheet has high strength, low sensitivity to cracks, good physical properties, good workability and corrosion resistance, and high strength can be obtained by age hardening. It has passed the "Weapon Equipment Quality Management System Certification".

The mechanical properties of 7068 aluminum alloy are much higher than those of the traditional 7xxx series ultra-high-strength aluminum alloy. Its tensile strength under T6511 treatment exceeds 700MPa, which is 11% higher than that of 7075 aluminum grade and Its elongation is also nearly 10%. It can be used to manufacture valve bodies and linkages of aerospace and vehicles and parts of bicycles and climbing equipment.

Original Source:https://www.aircraftaluminium.com/a/aircraft-aluminum-grade-7068-vs-7075.html