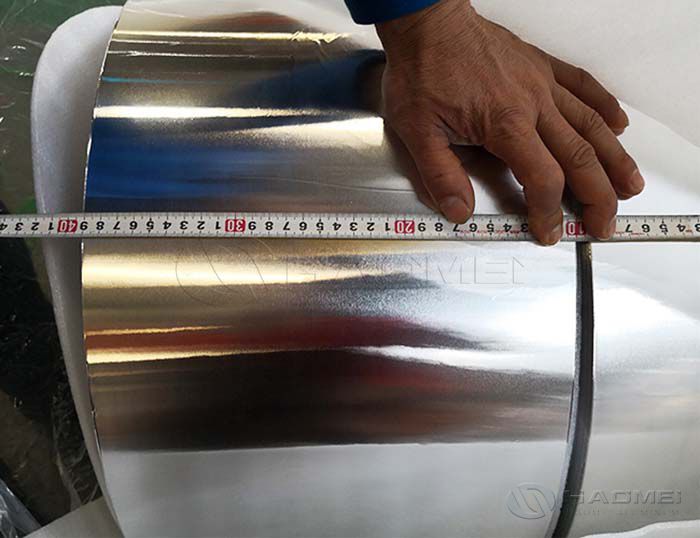

El rollo de papel de aluminio es uno de los elementos más versátiles de la cocina. El papel de aluminio de calidad alimentaria incluye 1235, 1060, 1100, 3003, 8011, 8021, 8079, etc. Tiene ventajas sobresalientes en barrera de gas, permeabilidad a la humedad, higiene y seguridad, eficiencia de producción, reciclabilidad y protección ambiental, etc. ¿Cuáles son los usos del papel de cocina?

Horneando

En la cocina, el papel de aluminio se usa a menudo para envolver alimentos, especialmente al hornear pan o calentar alimentos. Si los alimentos se introducen directamente en el horno para asarlos, es probable que se calienten de manera desigual y lenta.

Si la comida se envuelve en papel de aluminio y luego se hornea, la fuente de calor del horno se transmite al papel de aluminio y luego a la comida, de modo que el espacio cerrado entre la comida y el papel de aluminio generará vapor de agua y aire caliente, que no solo puede calentar la comida de manera uniforme, sino también acelerar el proceso de calentamiento.

Cubierta de tabla de molienda

Después de que el jengibre y el ajo se muelen en barro en la tabla de molienda, los residuos siempre quedan atrapados en los huecos de la tabla de molienda, lo que es problemático para limpiar y fácil de cortar las manos. Coloque el papel de aluminio con el lado brillante hacia arriba en la tabla de molienda y luego muela el barro, y los ingredientes no se pegarán.

Crema de conservación

La crema sin envasar se puede envolver en papel de aluminio y luego almacenar en el refrigerador. El efecto de conservación es mejor que el de la envoltura de plástico. Esto se debe a que el papel de aluminio tiene mejores propiedades de barrera que la envoltura de plástico, que puede aislar la mayor parte del aire, la humedad y la luz.

Eliminación de manchas

Siempre que sea una bandeja de metal, se puede limpiar con una bola de papel de aluminio. Por ejemplo, puede restregar la quemadura en una parrilla de barbacoa o en un horno.

Embudo

Si necesita verter cosas y no tiene un embudo en la cocina, enrolle el papel de aluminio en forma de cono. Puede contener cualquier líquido, incluso a altas temperaturas.

Almacenar plátanos

Envuelva la parte inferior del tallo (cola) del plátano en papel de aluminio y ponga la fruta en el refrigerador, durarán mucho más de lo habitual.

Protección del gabinete

El papel de aluminio tiene el efecto de bloquear las manchas de aceite, por lo que colocamos una capa de papel de aluminio en la parte inferior y el compartimento del gabinete. Incluso si algunos condimentos se derraman accidentalmente, es muy fácil de limpiar, evita que las manchas de aceite erosionen el gabinete y prolongue la vida útil del gabinete.

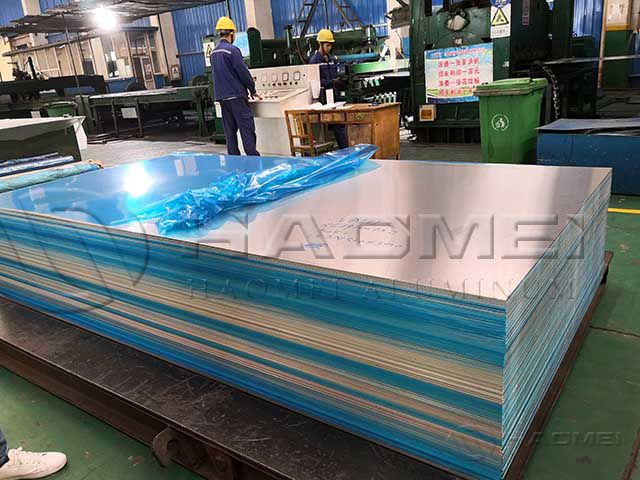

Haomei Aluminium tiene todos los principales grados de aleación de rollo de aluminio para cocina. Bienvenido a dejar un mensaje a continuación para consultar el precio del papel de aluminio.

fuente original: https://www.placadealuminio.es/a/rollo-de-aluminio-para-cocina.html

2014 aluminum alloy is Al-Cu-Mg-Si high-strength forged aluminum alloy, which can be strengthened by heat treatment. The chemical composition of the alloy is similar to that of 2A14 aluminum alloy, and it has high strength and good hot workability, and is easy to forge. The performance is basically the same as 2A14. Due to the high copper content of the alloy, its corrosion resistance is poor, and it is prone to intergranular corrosion and stress corrosion.

2014 aluminum alloy is Al-Cu-Mg-Si high-strength forged aluminum alloy, which can be strengthened by heat treatment. The chemical composition of the alloy is similar to that of 2A14 aluminum alloy, and it has high strength and good hot workability, and is easy to forge. The performance is basically the same as 2A14. Due to the high copper content of the alloy, its corrosion resistance is poor, and it is prone to intergranular corrosion and stress corrosion.