In the selection of materials for the C919 aircraft, a large number of traditional aluminum alloys are selected, such as 7075-T62, 7075-T73, 7050-7452, 7075-T73511, 7050-T77511, 7075-T7351, 7050-T7452, 7150-T77511, 7075- T6, 7055-T7751, 7055-T76511, 7085-TT651, 7085-T7452; 2024-T42, 2523-T3, 2024-T3511, 2024HDT-T351, 2026-T3511, etc.

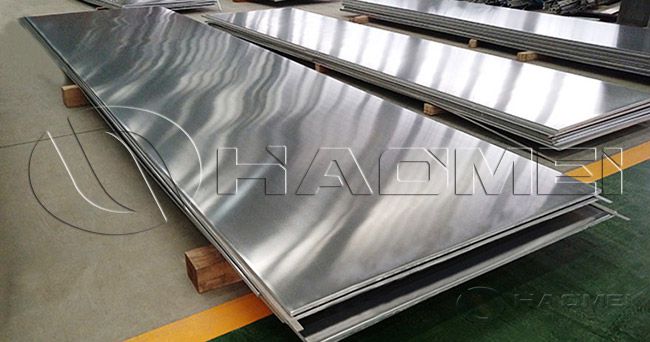

Aluminum alloy 7075 is mainly used in the manufacture of aircraft structures and other high-stress structural parts that require high strength and corrosion resistance, such as aircraft upper and lower wing panels, stringers, etc. After solution treatment, it has good plasticity, good heat treatment strengthening effect, good strength below 150 degrees, and particularly good low temperature strength.

Zinc is the main alloying element in the 7075 aluminum plate. The addition of magnesium to the alloy containing 3%-7.5% zinc can form MgZn2 with a significant strengthening effect, so that the heat treatment effect of the alloy is far better than that of the aluminum-zinc binary alloy.

The common tempers of 7075 aluminum sheet are T651, T6, T73, T76 and T74. Among the series, the 7075-T651 aluminum alloy is of the highest grade, and is known as an excellent product among aluminum alloys, with high strength far superior to any mild steel. What are 7075-t6 aluminum properties?

T6 temper has the highest strength, low fracture toughness, and is sensitive to stress corrosion cracking. Generally, it is not recommended for low temperature applications. The T73 process successfully developed in 1960 is an over-aging heat treatment process.

Compared with the T6 state, the material strength is reduced by 10%~15%, but it can effectively prevent stress corrosion cracking in the thickness direction, and has high fracture toughness and excellent stress corrosion resistance and exfoliation corrosion resistance performance.

Much like the 7075 aluminum alloy, the 2024 aluminum alloy is commonly used in aerospace applications. In particular, it is commonly used in aircraft wings and fuselages. 2024 aluminumis suitable for applications requiring high cyclic fatigue strength; while 7075 is suitable for applications requiring high stress/strain resistance.

Both alloys offer similar weldability. Spot or flash welding can be used, but arc and gas welding are not recommended. They all have similar machinability. 2024 has slightly better machinability and 7075 has slightly better corrosion resistance.

Original Source:https://www.aircraftaluminium.com/a/aircraft-aluminum-alloy-7075-t6.html