The pure aluminum is soft and low strength. The addition of elements such as Mg and Si can improve its mechanical properties and formability and get lower flexor ratio, higher processing hardening rate, uniform elongation,etc. The aluminum alloys used for body in white are mainly 5xxx and 6xxx aluminum alloys.

5xxx ABS aluminum like 5182 aluminum plate has the advantages of ordinary carbon steel plates in strength, formability, surface treatment and corrosion resistance, but has two disadvantages: delay yield and strecther-strainmark. The orange peel effect is prone to the formation of the sheet.

Increasing the Mg content can inhibit the generation of Luds lines to a certain extent, but with the increase in Mg content, the tensile performance decreases, and the processing hardening is severe. Therefore, they are usually used for the inner plate. 6xxx aluminum plate is for the outer panel of the car.

6xxx aluminum alloy has excellent comprehensive performance due to the addition of Mg-Si alloy elements. It is a good combination of good intensity and plasticity. Compared with the steel plate, the yield strength and tensile strength of the 6000 Series-T4 sheet is similar and the N value exceeds the steel sheet. In addition, it can also n achieve the intensive purpose after baking harden.

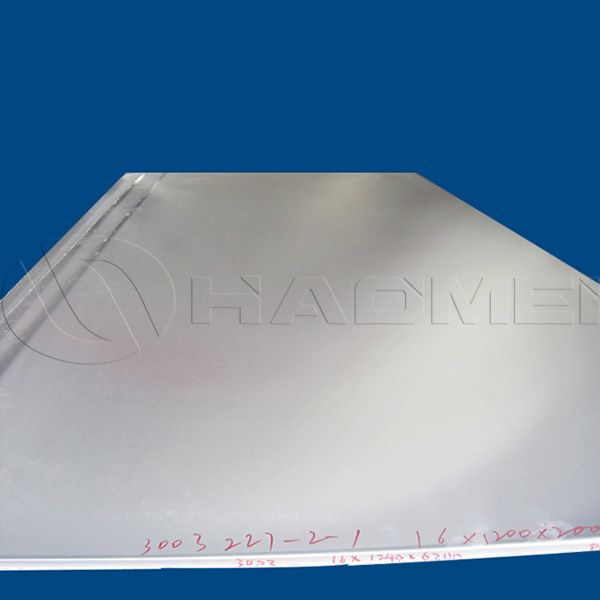

The aging variation of 5000 aluminum alloy is small, which can be regarded as having no age hardening. 6000 aluminum alloy has age hardening after being heat treated. For example, the yield strength of the new material is 130MPa, the yield strength of that after 3 months is 150MPa, and the yield strength of that after 6 months is 165MPa. If the storage time is more than 6 months, 6000 aluminum will have a difficult formation because it is too hard.

Haomei Aluminum has different alloys of car aluminum, including 5xxxx and 6xxx aluminum sheets. Welcome to leave message below to inquire what you need.

Original Source:https://www.autoaluminumsheet.com/a/5182-abs-aluminum-plate.html