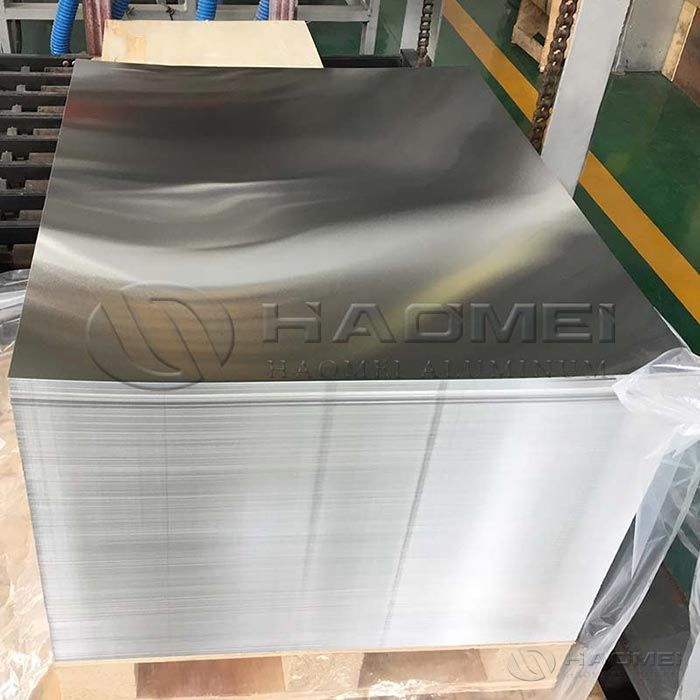

5083 aluminum factory belongs to 5xxx Al-Mg alloy. It is a typical anti-rust aluminum plate with good corrosion resistance, excellent weldability, and good cold workability. Its common tempers are H111/H112/H116/H321. It is widely used to make tank body, baffle and bulkhead.

The quality 5083 aluminum sheet is a foundation for the transportation safety of all tanker trucks. Tank body is the core of every fuel tanker. The tanker material is the main reference factor for customers to choose high-quality tanker. The 5083 alloy aluminum is the most widely used aluminum tanker plate.

Its main alloy element is magnesium, and the content of magnesium (Mg) can reach between 4.0% and 4.9%. Usually, the intermediate value of 4.5% is used in the production process. Therefore, 5083 aluminum plate is also called Almg4.5 aluminum alloy. It has good forming performance, good corrosion resistance and weldability,

5083 aluminum plate is of light weight, good rigidity and high strength. The 3.0mm thick aluminum plate weighs only 8kg per square and has a tensile strength of 100-280N/mm2, which is especially suitable for tank truck. 5083 has good corrosion resistance and stable chemical composition. It is suitable for all kinds of tankers.

EN AW 5083 h111 is often used for making tanker body. 5083-O is often used to make tanker head and baffle. Aluminum 5083 h111 features superior performance in extreme environment such as industrial chemical environment. Its strength can keep changing after welding.

Both 5754 aluminum plate and 5083 aluminum plate belong to aluminum-magnesium alloy. The main difference between the two is the content of magnesium alloy, hardness and elongation. The hardness of 5083 aluminum plate is higher than that of 5754 aluminum plate. Of course, the price of 5083 aluminum plate is relatively high.

Original Source:https://www.aluminumtankerplate.com/a/5083-aluminum-factory-for-fuel-tanker.html