Aluminum alloy has been used in the shipbuilding industry for nearly a hundred years. With the rapid development of shipbuilding industry at home and abroad, the lightweight of ships has been paid more and more attention. Due to the low density, high strength, high rigidity and corrosion resistance of aluminum, the ships made of aluminum alloy like AW 5083 h111 are 15-20% lighter than ships built with steel and other synthetic materials.

The high toughness, corrosion resistance and weldability of aluminum alloy provide a good choice for building ships with strict weight requirements. Because aluminum has a lower processing cost, it is more economical to use aluminum to make ships. From the perspective of ship designers, ships made of aluminum alloys can achieve higher speeds and longer service lives.

The aluminum alloys used on ships can be divided into deformed aluminum alloys and cast aluminum alloys. The marine grade aluminum has been used on different kinds ships including all-aluminum marine research ships, ocean-going commercial ships and passenger ships,hydrofoil, hovercraft, passenger ferry, catamaran, transportation boat, landing craft,etc.

Because marine aluminum alloys have special requirements for strength, corrosion resistance, weldability, etc., aluminum-magnesium alloys, aluminum-magnesium-silicon alloys and aluminum-zinc-magnesium alloys are mostly used for shipbuilding.

The marine grade aluminum sheet can be divided into aluminum alloys for ship hull structures and aluminum alloys for outfitting according to their uses. The aluminum alloy used in the hull structure of the ship is mainly 5083, 5086 and 5456, especially Almg4 5mn0 7 h111. The 6000 series alloy is mainly used for the superstructure of the ship because of the intergranular corrosion in the seawater.

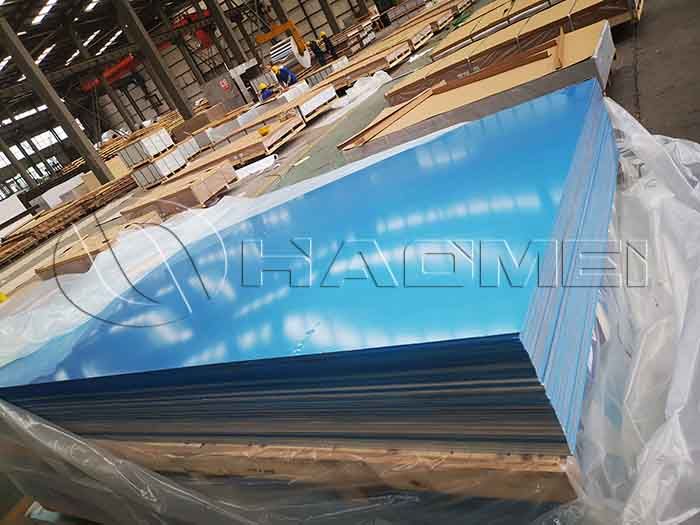

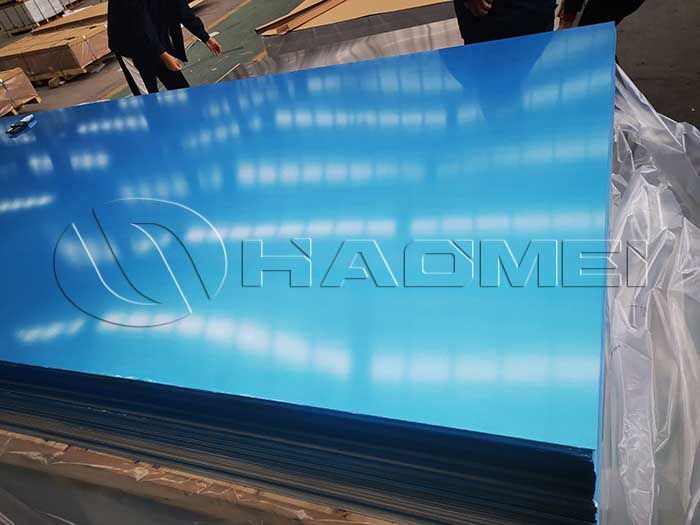

In terms of the comprehensive performance, 5xxx aluminum is the best marine grade aluminum for the ship building. Haomei Aluminum has different marine grade aluminum sheets. Welcome to leave message below to inquire what you need.

Original Source:https://www.marinealu.com/a/what-is-the-best-marine-grade-aluminum.html