Aluminum and aluminum alloys are used more and more widely in the shipbuilding industry, ranging from small motorboats to 10,000-ton oil tankers, from offshore hovercraft to submarine . The marine grade aluminium sheet is used to make ship shells, support structures, supporting facilities, pipelines, etc.

The aluminum sheet used in the marine industry can reduce the overall weight of the ship, increase the speed of the ship, and resist the corrosion of the ship by seawater. It is mainly divided into aluminum-copper alloys, aluminum-magnesium alloys and aluminum-silicon alloys.

Aluminum-magnesium alloys are mainly used for hull shells, water pump pipes, pump shells and frame brackets, etc. The grades are 5083, 5086, 5456, 5466, etc. 5083 aluminum plate can be regarded as its typical one. The common tempers are O, H111, H112, H116 and H321,etc. It has medium strength, good corrosion resistance and formability, high fatigue resistance, and is generally used as the main structure of the hull.

7075 aluminium sheet belongs to the Al-Zn-Mg-Cu series. It has good corrosion resistance, good oxidation resistance, good easy processing and wear resistance, and good workability. It has high strength below 150℃, and has particularly good low temperature strength. However, it has poor welding performance, and stress corrosion cracking tendency.

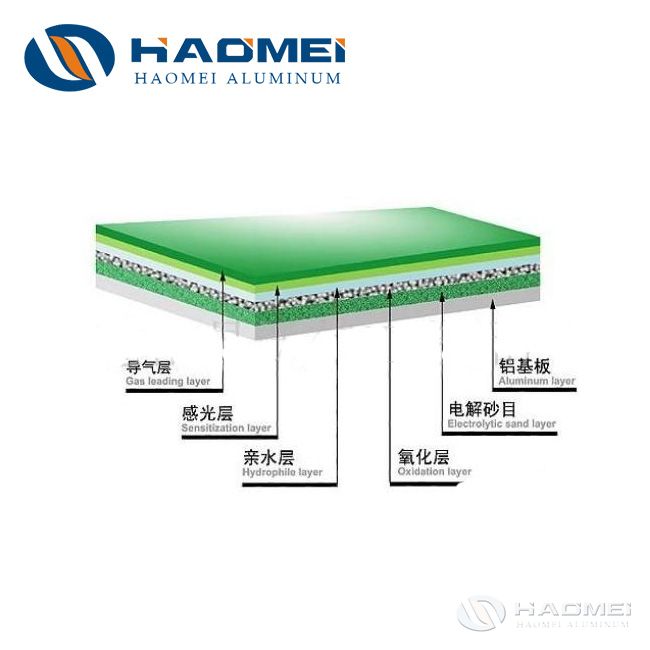

6061 aluminum sheet has excellent processing performance, excellent welding characteristics and electroplating properties, good corrosion resistance and excellent anodizing effect. The commonly used plates include thin plates over 1.6mm and thick plates over 30mm. In order to prevent slip, the deck adopts 6061 textured aluminium sheet.

Original source: https://www.hm-alu.com/a/types-of-marine-grade-aluminium-sheets.html