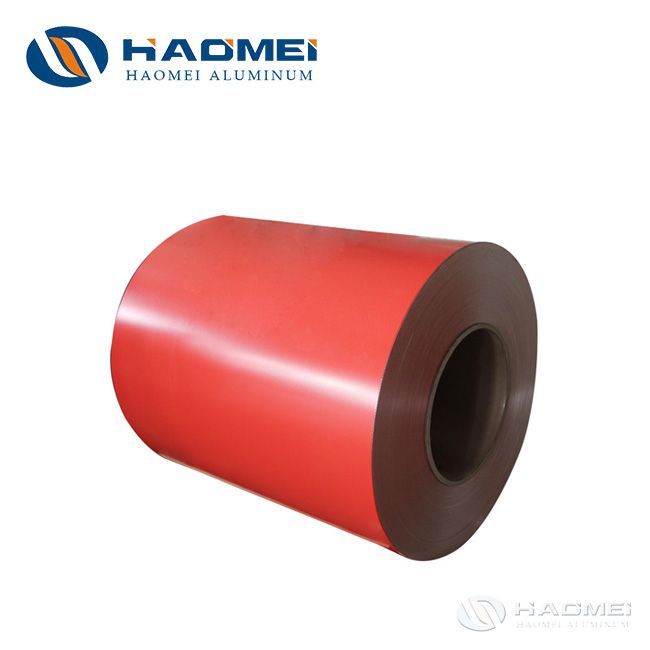

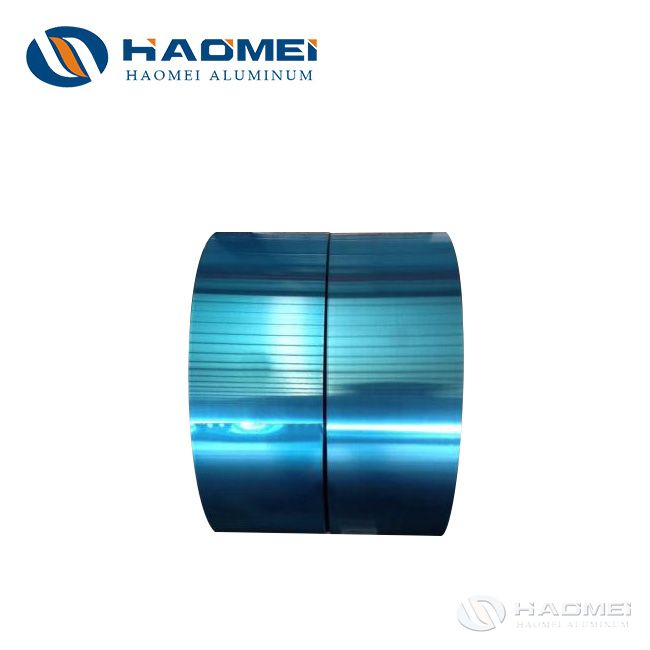

The coated and embossed aluminum strip has been used as rain gutter because of the good formability, durability and strong decoratin. The common alloys of aluminum strip for rain gutter are 3105 and 3003. Both sides of the aluminum strip are usually coated with the same coating, but often in different colors. This allow customers have extra choice while increasing the performance of the sink.

The type and thickness of the coating depends on the balance between cost-effectiveness and performance. The service life of the color coated aluminum strip depends on many factors, including outdoor conditions, no contact with corrosive matter, cleanliness degree,etc.

Before coating, Haomei Aluminum has a unique pretreatment process. This method forms an aluminum oxide film on the aluminum surface, which is a flexible porous structure. This pretreatment makes our aluminum strip has better paint adhesion.

The common specification offered by Haomei Aluminum, aluminum strip roll manufacturer is as the following:

Aluminum alloy: 1100 and 3003

Temper: H14

Coating: PE or PVDF

Aluminum strip thickness: 0.3-1.0 mm

More and more modern families choose to use the shutter made of the coated and embossed aluminium strip. The main reason is that the coated aluminum strips have a variety of colors and patterns to choose from, bringing to vitality to the room. What are its main advantages?

More and more modern families choose to use the shutter made of the coated and embossed aluminium strip. The main reason is that the coated aluminum strips have a variety of colors and patterns to choose from, bringing to vitality to the room. What are its main advantages?