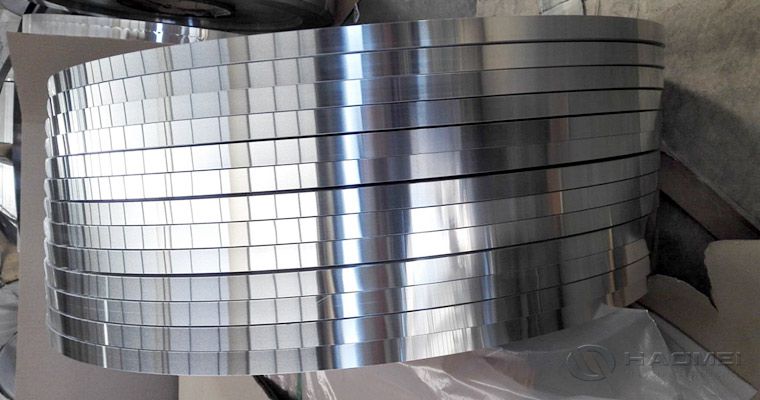

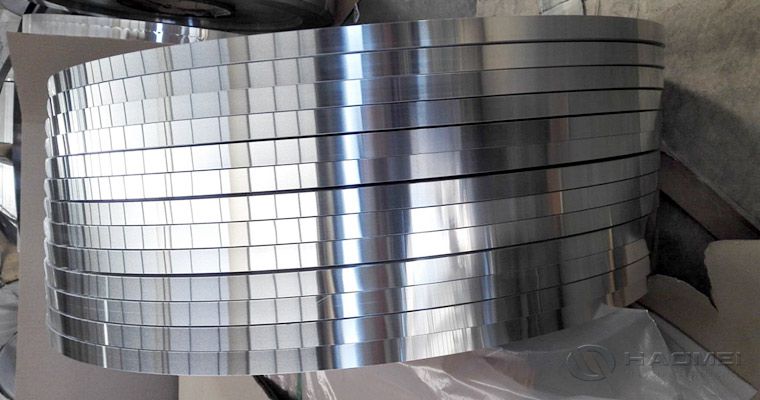

Aluminum strip for transformer is mainly used in large transformers , solar energy and power industry. The common alloys are 1050, 1060,1070 and 1350 aluminum strips with O temper. The thickness is within 0.2-3mm.

The surface quality of the aluminum strip for transformer winding:

1. The edge of aluminum strip is neat and clean, and free of burs, cracked edges, scratches,those defects.

2. The surface of the aluminum strips are flat.

3. The surface of the aluminum strips is clean, without corrosion marks, oil marks, wrinkles, seams, scratches, bright and dark lines, rubber roller marks, vibration marks, twills, etc.

4. There are no bright spots, roller marks, wheel marks and black lines on the surface of aluminum strip.

5. The surface of the finished aluminum strip is free of yellow oil spots, oil sticking, blistering and tearing phenomena formed by the burning of lubricating oil.

6. Resistivity is less than or equal to 0.028.

7. After chamfering process, the edge of aluminum strip is of round corner and zero burrs.

How to Package Aluminum Fin Stock

There are two packaging methods: jumbo roll packaging and wooden box packaging.

Jumbo roll packaging: The size of the large roll are determined by the width and length customized by the customer.

Wooden box packaging: The general size of the wooden box is 1.4m*1.3m*0.8m. The customer's requirements for aluminum strip width and roll diameter are the deciding factors for the size of the wooden box.