This year, with the outbreak of he coronavirus, the production and sales of masks have increased substantially worldwide. Masks can prevent the spread of droplets and prevent the invasion of bacteria and viruses, and are an important means of protection.

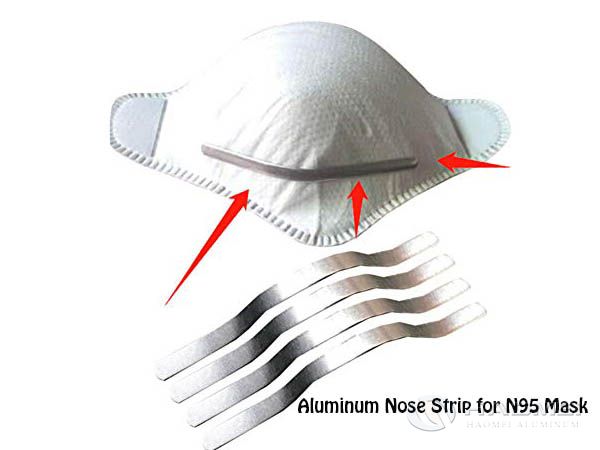

In addition to strict standards for non-woven materials and technologies, masks that meet the protection requirements also need quality aluminum nose strip. The role of the aluminum nose strip in the masks is mainly to match the shape of different people's faces.

In addition to strict standards for non-woven materials and technologies, masks that meet the protection requirements also need quality aluminum nose strip. The role of the aluminum nose strip in the masks is mainly to match the shape of different people's faces.

The common aluminum strip for face mask mainly has three series: 1060. 3003 and 5005 aluminum strip. Different from the common aluminum strips, aluminum strip for masks need to has strong rust resistance, corrosion resistance, high brightness, good straight line, good toughness and good sealing effect.

3003 aluminum nose wire exactly satisfies all these requirements. It belongs to aluminum-manganese alloy series. With manganese alloy element, this product has excellent anti-rust properties and its strength is about 10% higher than 1100. Better formability, weldability and corrosion resistance makes it an ideal choice for N95 masks.

The specification of 3003 aluminum nose wire:

1. Aluminum alloy: 3003

2. Temper: O

3. Surface: Mill finish

4. Thickness: 0.4*0.5 mm

5. Width: 90-100 mm

If you need this aluminum strip for face mask, welcome to contact Haomei Aluminum.

Original source: https://www.hm-alu.com/a/3003-aluminum-nose-wire.html

In addition to the 95% filtration efficiency, another important factor is that the N95mask fits closely with the face. These two factor contributes to the superior protection function both in medical environment and common surroundings. The close fit depends on aluminum nose strip for face mask.

In addition to the 95% filtration efficiency, another important factor is that the N95mask fits closely with the face. These two factor contributes to the superior protection function both in medical environment and common surroundings. The close fit depends on aluminum nose strip for face mask.