As our best selling series, Aluminum coil with kraft paper is of superior insulation effect, moisture resistance and corrosion resistance. We also have Polysurlyn Laminated Aluminum Coil. Welcome to get quotation by emailing us: dolly@alumhm.com or visit: https://www.alumhm.com/aluminum-coil/

With 20 years'development, Haomei has grown into a top aluminium alloy manufacturers and suppliers. We have comprehensive kinds of aluminium sheets, aluminum coil, aluminum strip, aluminum foil, aluminum discs, aluminum tread plate, color coated aluminum and CTP plates, covering series-1, series-3,series-5, series-6 and series-8. You can realize one-stop purchase in Haomei.

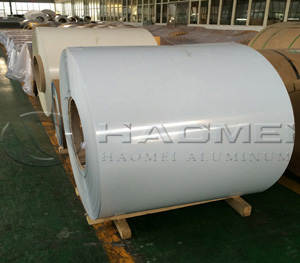

What Do You Like to Know About Coated Aluminum Coil

Coated aluminum coil has been a favorable material in many fields like building decoration, electronics, furniture, lighting,etc. What do you like to know about it? Here is an encyclopedical introduction of coated aluminum coil.

What Is Color Coated Aluminum Coil

After the aluminum coil is cleaned, chromized, roll coated, baked, etc., the surface of the aluminum coil is coated with various colors of paint.

What Are the Aluminum Trim Coil Colors

The aluminum trim coil colors  are really various: white powder coated aluminium, black trim coil, brown aluminum trim coil,copper colored aluminum coil, gold trim coil,etc. It also has different patterns like wood grain, stone gran, brick pattern, camouflage, fabric pattern,etc.

are really various: white powder coated aluminium, black trim coil, brown aluminum trim coil,copper colored aluminum coil, gold trim coil,etc. It also has different patterns like wood grain, stone gran, brick pattern, camouflage, fabric pattern,etc.

are really various: white powder coated aluminium, black trim coil, brown aluminum trim coil,copper colored aluminum coil, gold trim coil,etc. It also has different patterns like wood grain, stone gran, brick pattern, camouflage, fabric pattern,etc.

are really various: white powder coated aluminium, black trim coil, brown aluminum trim coil,copper colored aluminum coil, gold trim coil,etc. It also has different patterns like wood grain, stone gran, brick pattern, camouflage, fabric pattern,etc.

Painted Aluminum Coil Thickness

It can be divided into single coating (4µm-20µm), double coating (25µm-28µm) and three coating (35µm-38µm). It is certain that the thicker coating are also available. That is usually made according to the customer’s requirements.

What Are Trim Coil Uses

In Construction Field: aluminum plastic panel, aluminum honeycomb sheet, Al-Mg-Mn roofing system, aluminum ceiling, shutters, roller shutter door, garage door, gutter,etc.

In Electronic Appliances: computer case, electrical panel, mobile phone shell,etc.

Other fields: lighting, furniture, solar reflector, packaging,etc.

Types of Aluminium Colour Coated Coils

There are four types: PVDF color coated aluminum coil, Polyester coated aluminum coil, Epoxy painting aluminum, and Acrylic painted aluminum coil.

There are four types: PVDF color coated aluminum coil, Polyester coated aluminum coil, Epoxy painting aluminum, and Acrylic painted aluminum coil.

What Are The Superior Properties

- Good temperature resistance

- Eco-friendly. It is safe to environment and human and it is easy to recycle.

- Super weather resistance and corrosion resistance

- The color is uniform and permanent. The luster can be kept fresh about at least 15 years.

- It is of rigid and tough combination. The strength of the coated aluminum coil is very high.

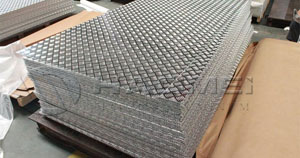

What’s the Advantage of 6061 Embossed Aluminum Sheet in Shipbuilding Industry

Ship is always in a surrounding of sea water, sun exposure, wind erosion, especially the deck. In addition, due to human activities and mechanical operations, the deck is often subject to stepping friction and crushing wear, and it is easily polluted by various oily, acidic and alkaline media.

Therefore, the ship deck material should be of excellent corrosion resistance, water resistance, weather resistance, anti-skid property,abrasion resistance and adhesion. Which kind of aluminum sheets satisfies the requirements? 6061 stucco embossed aluminum sheet is an ideal choice. It is of excellent corrosion resistance, weather resistance and non-slip resistance. More importantly, it is easy to process.

Therefore, the ship deck material should be of excellent corrosion resistance, water resistance, weather resistance, anti-skid property,abrasion resistance and adhesion. Which kind of aluminum sheets satisfies the requirements? 6061 stucco embossed aluminum sheet is an ideal choice. It is of excellent corrosion resistance, weather resistance and non-slip resistance. More importantly, it is easy to process.

What processing technologies do we have to ensure the quality of 6061 aluminum plate? We have two quenching lines to achieve continuous quenching , improving production speed and ensuring stable product performance at the same time. The whole process only take 8- 16 hours, greatly shortening the production circle.

We choose Italian Herkues grinding machine equipment, ensuring the precise operation of the rolling equipment, thus improving the surface quality of the embossed aluminium sheet. The product not only has high gloss, but also has no visible defects.

We choose Italian Herkues grinding machine equipment, ensuring the precise operation of the rolling equipment, thus improving the surface quality of the embossed aluminium sheet. The product not only has high gloss, but also has no visible defects.

With such advanced processing craft and equipment, our 6061stucco embossed aluminum sheet is of novel pattern, light weight and excellent durability. Its tensile strength reaches 200N per square millimeter and it has high elongation, which is higher 10% than the average level.

Top Five Popular Aluminum Sheet Types

Different series of the aluminum alloys have great differences in its physical properties, thus influencing its applications. Some of them have excellent performance in their respective fields, therefore they are better known than others. What are they? In this page, we would introduce the top five popular types.

The 1000 Series aluminum sheet is a pure aluminum sheet, of which the aluminum content is over 99%. Its representatives are 1050 aluminum sheet. 1050 aluminium alloy is an aluminium-based alloy in the "commercially pure" wrought family. It is commonly used in the electrical and chemical industries, on account of having high electrical conductivity, corrosion resistance, and workability.

The 2000 series aluminum plate is characterized by high hardness, of which the copper content is the highest, about 3-5%. Its representative is the 2024 sheet. The 2024 aluminum coils and sheets are considered the "aircraft" alloy because of its strength. Among the tempers of the 2024 sheets, the 2024 t3 aluminum sheet is more used.

The production process of the 3000 series aluminum plate in China is excellent. The 3003 aluminum plate is a typical Al-Mn alloy. This material is of good formability, excellent corrosion resistance and good weldability. Due to great corrosion resistance, the 3003 aluminum sheet is widely used in shipbuilding.

The production process of the 3000 series aluminum plate in China is excellent. The 3003 aluminum plate is a typical Al-Mn alloy. This material is of good formability, excellent corrosion resistance and good weldability. Due to great corrosion resistance, the 3003 aluminum sheet is widely used in shipbuilding.

The 5000 series aluminum sheet is a common aluminum sheet series, of which the main element is magnesium. It is one of the most mature aluminum sheet series of Haomei Aluminum.

The 5052 aluminum sheet is the most well-known marine grade aluminium sheet. Common uses for this alloy include marine parts, home appliances, food equipment, fuel tanks, storm shutters, refrigerators, aircraft tube, fences, etc.

The main elements of the 6000 series aluminum sheet is magnesium and silicon besides aluminum.

6061 aluminum plate is one of the most versatile of the heat-treatable alloys. 6061 sheet is popular for its medium to high strength requirements, good toughness and excellent corrosion resistance.

Original Source: https://www.alumhm.com/a/top-five-popular-aluminum-sheet-types.html

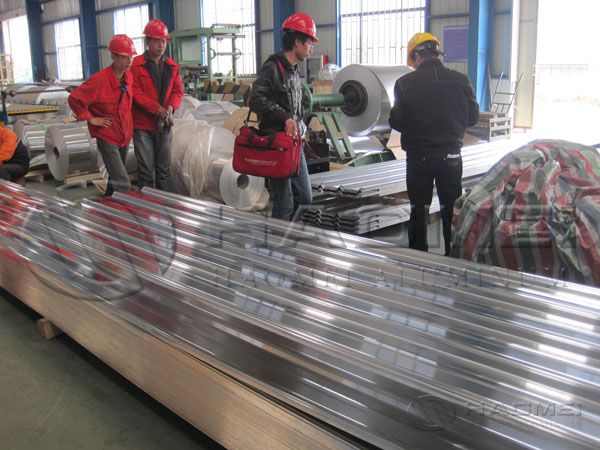

Aluminum Roofing Sheets Manufacturing Process|Price in Ghana

As an aluminum sheet manufacturer, Haomei offers you rich types of aluminum roofing sheet/corrugated aluminum sheet. This is the manufacturing process of parts of them like zinc aluminum roofing sheet, long span and short span aluminum roofing sheet. Get quotation now by emailing us: sale@alumhm.com

50 Tons of Aluminium Roofing sheet Best Price to Egypt

Product Name: Long Span Aluminum Roofing Sheet

Amount: 50 Tons

Destination: Egypt

Delivery Date: November, 2019

Get Quotation: If you like to know aluminium roofing sheet price, welcome to email us directly: feedom@haomeicn.com

Specification of aluminium sheet roofing:

Product

|

Zinc aluminium roofing sheets

|

Standard

|

JIS G3302 ASTM 653M/EN 10142

|

Material Grade

|

SGCC / SGLCC / DX51D+Z / DX51D+AZ, etc

|

Thickness

|

0.12mm-2.0mm

|

Width

|

600-1250mm(or as your requirement)

|

Length

|

Customized

|

Zinc-coating

|

30g/m2-275g/m2

|

Wave Height

|

17-18mm or according to request

|

Paint coating

|

top 15-25 microns/back 5-7 microns

|

Surface coating

|

Galvanized, Color coating

|

Sheet weight

|

3-5MT

|

Package

|

standard seaworthy packing

|

Technique

|

Raw material: Hot rolled steel coil --> Cold rolled—>hot dipped galvanizing—>corrugated

|

订阅:

评论 (Atom)

How Is FSW Aluminium for Shipbuilding Produced #aluminum #shipbuilding

Haomei Aluminum provide wide and extra wide aluminum FSW plate for the superstructure of the ships. It will help you shorten the constructio...

-

The plate used in the CTF process is mainly PS plate , which is pre-coated photosensitive plate, which is developed to adapt to the rapi...

-

With the spread of energy saving and emission reduction concept, lightweight vehicles have been quickly promoted. Aluminum alloy is one of...

-

In the vast world of aluminum alloys, 5052 and 5754 aluminum alloys have become effective materials in many fields due to their unique pro...